1. Introduction

If you’ve ever tried soldering and ended up with a dull, crusty joint that barely sticks, chances are you skipped one of the most essential steps: using flux when soldering. Flux might sound like some obscure chemical from a high school lab, but in the world of soldering, it’s a game-changer. In this post, we’ll break down what flux is, how it works, the different types you can use, and why it’s the not-so-secret weapon for anyone who wants clean, strong solder joints. So, let’s dive in.

2. What Is Flux, really?

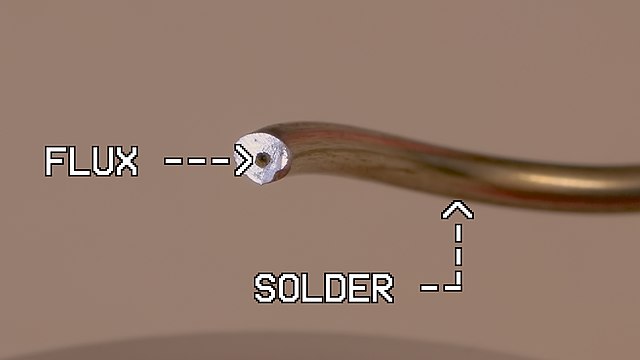

Flux is a chemical cleaning agent used during the soldering process to remove oxidation from metal surfaces. When two metal surfaces are heated, they naturally form a layer of oxide that prevents solder from bonding properly. Flux eliminates this oxide layer, allowing molten solder to flow more easily and stick more effectively to the components and pads.

But that’s not all—flux also helps prevent new oxidation from forming during the soldering process. In short, it ensures the metal surfaces are as clean and bondable as possible. Without flux, your solder joints can end up weak, unreliable, or just plain ugly.

3. Types of Flux (And When to Use Them)

There are several types of flux, each suited for different use cases:

Rosin Flux: This is made from natural resin and is one of the most commonly used fluxes in electronics. It’s effective, easy to find, and cleans well during soldering. However, it often leaves behind residue that needs to be cleaned.

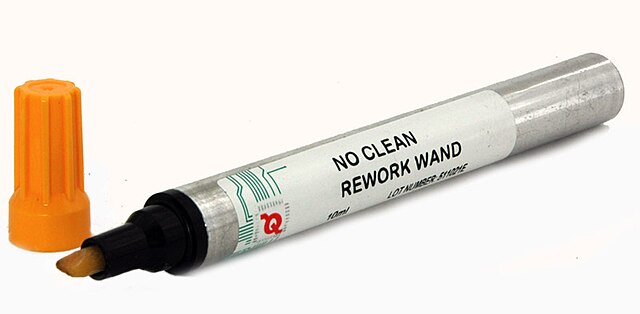

No-Clean Flux: As the name suggests, this type doesn’t require cleaning after soldering. It produces less residue and is ideal for quick jobs or mass production. However, it’s not always as aggressive at removing oxidation.

Water-Soluble Flux: This flux is highly active and great at removing oxides, but it must be cleaned thoroughly with water after use to prevent corrosion.

Paste Flux: This thick, sticky variant is useful for surface-mount soldering or when precise application is needed. It’s often used in conjunction with hot air rework stations.

Choosing the right flux depends on your project type, components, and whether you’re okay with cleaning up afterward.

From my experience, if you’re just getting started with electronics, flux-core solder wire makes things much easier. You won’t need to worry about which flux to pick—it’s already inside the wire.

4. How to Use Flux Properly

Using flux isn’t simple, especially the first time but there are a few best practices:

Apply a small amount of flux directly onto the area to be soldered. You can use a brush, a syringe, or even a Q-tip.

Heat the joint with your soldering iron and then apply the solder. The flux will activate, clean the surface, and allow the solder to flow smoothly.

Avoid using too much flux. Overapplication can lead to sticky residue, messy boards, and potential long-term issues.

Flux should be applied just enough to cover the area of the joint—think of it as seasoning, not sauce.

5. Common Mistakes with Flux

Even though it’s a simple concept, many beginners make avoidable mistakes with flux:

Using too much: More isn’t always better. Excess flux can burn, create fumes, and leave behind unnecessary residue.

Not cleaning residue when needed: If you’re using rosin or water-soluble flux, the leftover gunk can become corrosive over time if not cleaned.

Assuming all flux is no-clean: Always check the type of flux you’re using; not all are safe to leave on your board.

Skipping flux entirely: This is the big one—don’t expect clean, reliable joints without it.

6. Recommended Flux Products

If you’re new to soldering, here are a few solid options to get started:

Kester 951 No-Clean Flux Pen – Easy to apply and great for small electronics projects

MG Chemicals Rosin Flux Paste – Reliable, strong cleaning power

Amtech NC-559-V2-TF – A cult favorite for SMD work

Always read the label and check what type of flux you’re buying. You don’t want to accidentally end up with plumbing flux!

7. Conclusion

Flux might not be the flashiest part of your soldering setup, but it’s absolutely one of the most important parts when you want to have a good circuit. From cleaning metal to ensuring proper bonding, this little helper can make or break your soldering project. Whether you’re a total beginner or just looking to up your game, understanding flux is key to getting those clean, strong, shiny solder joints we all dream about when making a good circuit.

So next time you pick up the soldering iron, don’t forget the flux—it’s the hero of every beautiful circuit.

[…] Not sure what flux does? Read our guide: What is Flux and Why Do You Need It for Soldering? […]

[…] So you’ve got your solder and flux figured out — awesome. If not, check out: What is Solder? (And How to Choose the Right One)Still confused about flux? What is Flux and Why It Matters in Soldering […]

[…] Recommended for: General soldering, Arduino, PCBs👉 Check this top-rated flux-core solder wireAlso read: What Is Flux in Soldering? A Beginner’s Guide to Cleaner, Stronger Joints […]