If you’re diving into DIY electronics, soldering is one of those must-learn skills — and solder itself is at the heart of it. But what exactly is solder? Why does it sometimes work perfectly, and other times, act like it wants nothing to do with your components?

In this guide, we’ll break down what solder actually is, the types you’ll come across, when to use each, and how to pick the right one for your projects.

What Is Solder?

Solder is a metal alloy that melts at relatively low temperatures — typically between 183°C and 225°C, depending on the alloy. This is considered low when compared to common metals like copper (~1,085°C), aluminum (~660°C), or steel (>1,370°C).

This relatively low melting point is what makes solder perfect for electronics — it can create strong connections without damaging sensitive components or circuit boards.

What Is Solder Made Of?

Solder is typically made from a mix of tin (Sn) and other metals like lead (Pb), silver (Ag), and copper (Cu). The blend affects the melting temperature, flow characteristics, and strength of the solder.

- Tin (Sn): The main ingredient in most solders — provides good conductivity

- Lead (Pb): Lowers the melting point, makes the solder flow easier (but toxic)

- Silver (Ag): Improves strength and conductivity

- Copper (Cu): Enhances strength and thermal performance

Types of Solder (By Composition)

| Feature | Leaded Solder (Sn-Pb) | Lead-Free Solder |

|---|---|---|

| Melting Point | ~183°C | ~217–225°C |

| Ease of Use | Easy for beginners | ❌ Harder to control |

| Flow & Wetting | Excellent | ❌ Less smooth flow, more prone to cold joints |

| Health & Safety | Toxic (lead fumes), not eco-friendly | Safer, environmentally friendly |

| Regulatory Compliance | Not RoHS compliant (banned in many countries) | RoHS compliant, legal for commercial use |

| Use Case | DIY, hobby, repairs | Manufacturing, consumer electronics, export |

| Skill Level | Ideal for beginners | Requires more experience |

| Where It’s Banned | EU, Japan, Korea (commercial use only) | Allowed worldwide |

Want to try both types? Here are two great options on Amazon:

- Leaded solder wire (Sn-Pb) – smooth flow, great for beginners

- Lead-free solder wire – RoHS compliant and safe for commercial use

Regulatory Compliance

If you’re making electronics for fun or learning, using leaded solder is totally fine — it’s easier to work with and great for beginners.

But if you’re selling your product, especially in regions like the EU, Japan, or South Korea, you need to use lead-free solder to comply with RoHS regulations (Restriction of Hazardous Substances). These rules ban the use of toxic materials like lead in consumer electronics.

Solder Forms: Wire, Paste, and Bar

Solder comes in a few different forms depending on how it’s used:

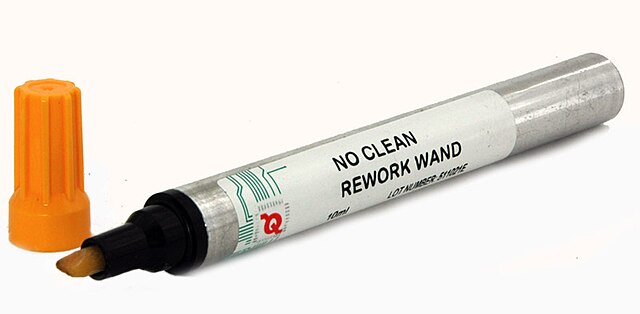

- Wire solder: The most common type for hand soldering. Often includes a flux core

- Solder paste: A mix of powdered solder and flux. Used for surface-mount (SMD) components with reflow soldering.

- Solder bar: Used in industrial applications (like wave soldering).

Also worth noting: rosin-core wire solder contains flux in the center — very convenient for electronics work.

When to Use Each Type

| Project Type | Recommended Solder |

|---|---|

| DIY or hobby electronics | Leaded solder (easy to work with) |

| Commercial / consumer products | Lead-free solder (RoHS compliant) |

| SMD / Reflow soldering | Solder paste |

| Large wires, connectors | Thicker wire solder |

Tips for Choosing the Right Solder

- Beginners should start with leaded solder (if legal in your area). It’s more forgiving.

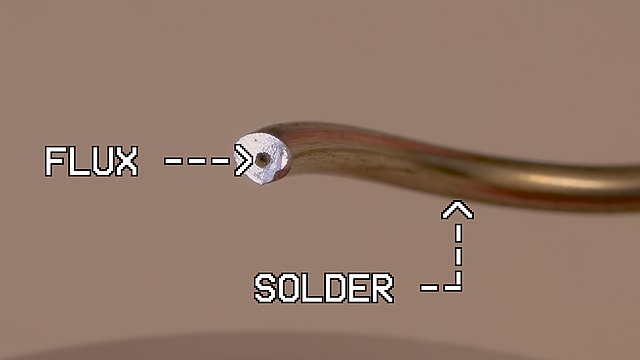

- Check for a flux core inside the solder wire. Flux helps clean the surfaces and improves solder flow.

Not sure what flux does? Read our guide: What is Flux and Why Do You Need It for Soldering?

3. Avoid ultra-cheap solder — inconsistent quality can ruin your joints.

4. Pick the right diameter:

- 0.6–0.8mm is great for fine electronics

- 1.0mm or larger for power connections

Need help picking? This soldering starter kit includes everything: solder wire, iron, flux, and stand.

This page includes affiliate links. I may earn a small commission if you purchase through them – at no extra cost to you.

Common Questions

1: Is solder reusable?

Technically yes, but the joint quality may suffer. It’s better to use fresh solder.

2: Does solder expire?

Yes — over time, especially if exposed to moisture. Most rolls have a shelf life of 1–3 years.

3: Can I mix leaded and lead-free solder?

It’s not ideal — the resulting mix might perform unpredictably. Stick with one type per project.

4: How do I store solder?

Keep it in a cool, dry place. Reseal rolls when not in use to prevent oxidation.

Summary

- Solder is essential for joining metal parts in electronics

- Leaded solder is easier to use but not RoHS compliant

- Lead-free solder is required in most commercial applications

- Choose based on your use case, skill level, and legal requirements

Pro tip: Start with leaded solder to build your skills — then level up to lead-free once you’re comfortable.

[…] you’ve got your solder and flux figured out — awesome. If not, check out: What is Solder? (And How to Choose the Right One)Still confused about flux? What is Flux and Why It Matters in […]