Motors are the hidden powerhouse behind much of the movement we encounter in our daily lives — from the buzz of a mobile phone to the precision motion of robotic arms and 3D printers. In the world of DIY electronics, robotics, and Arduino projects, understanding how motors work is an essential skill.

In this ultimate beginner’s guide, we’ll explore the history of electric motors, break down the fundamentals of how motors work, cover the different types of motors used in electronics, and explain how to choose the right one for your project.

1. A Brief History of Electric Motors

Electric motors didn’t appear out of thin air — they are the result of centuries of scientific breakthroughs in electromagnetism and engineering.

- 1821 – Michael Faraday demonstrated the first electromagnetic rotation using a current-carrying wire and a magnet, laying the foundation for all electric motors.

- 1831 – Faraday’s law of electromagnetic induction was published, providing the theoretical basis for converting electrical energy into mechanical motion.

- 1873 – Zénobe Gramme showcased one of the first practical DC motors that could perform continuous work.

- 1888 – Nikola Tesla developed the AC induction motor, a major innovation that would become widely adopted in industrial applications.

- 20th Century – Motors evolved rapidly, becoming smaller, more efficient, and programmable with the rise of solid-state electronics.

Today, electric motors are embedded in almost every electronic device, from smartwatches to electric vehicles, and are critical to automation and robotics.

Understanding this history helps you appreciate the technological marvel that even the simplest motor represents Today, it’s nearly impossible to imagine a world without motors. From the tiny vibration motor in your phone to the powerful drivetrain in electric cars, they are indispensable to both consumer electronics and industrial automation.

2. What Is a Motor?

A motor is an electromechanical device that converts electrical energy into mechanical energy. This transformation allows electronic systems to physically move things — wheels, fans, gears, robotic arms, and more. Motors are essentially what give robots and machines their ability to interact with the physical world.

The motion produced by motors is usually rotational, but some motors produce linear movement using specialized designs, such as lead screws or linear actuators.

How It Works:

The core principle behind most motors is electromagnetism. When an electric current passes through a conductor (like a wire) in a magnetic field, it experiences a force (Lorentz force). This force is used to create torque, which spins the motor’s shaft. The direction and magnitude of the force are determined by the direction of current and strength of the magnetic field.

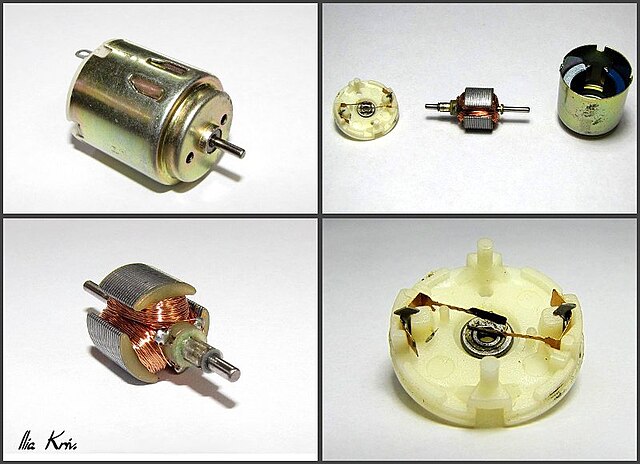

There are some basic components of a motor :

- Rotor (Armature): The spinning part of the motor that delivers mechanical output.

- Stator: The stationary part, often housing magnets or windings containing permanent magnets or electromagnets to generate the magnetic field.

- Commutator and Brushes: Found in brushed DC motors to reverse current flow as the motor spins motors to switch current direction and maintain rotation.

- Bearings: Allow smooth and stable rotation of the shaft.

Common Motor Terms You Should Know about DC motors:

- Torque (Nm): The amount of rotational force the motor produces — higher torque means more pulling or pushing power.

- RPM (Revolutions Per Minute): HowA measure of how fast the shaft spins is rotating.

- Voltage (V): The electrical pressure required needed to drive the motor.

- Current (A): The amount of electricity drawn flow of electricity required by the motor under load.

- Efficiency (%): How well it converts electrical energy into motionthe motor converts electricity into usable mechanical work.

Understanding these elements helps you evaluate motor performance and decide how to integrate motors into your DIY or industrial project.

3. Understanding DC Motors (Direct Current Motors)

A DC motor is one of the most basic and widely used motor types, especially in low-voltage electronics and beginner projects. When a DC voltage is applied to the motor’s terminals, it produces rotational motion a type of electric motor that runs on direct current. It is commonly used in portable electronics, robotics, and automotive systems because of its simplicity and effectiveness at low voltages.

So, how do DC Motors Work?

When voltage is applied across the motor terminals, current flows through the coil windings inside the rotor. This generates a magnetic field that interacts with the stator’s magnetic field, creating rotational force. The commutator switches the direction of current each half-turn, ensuring that continuous DC motors typically use a brushed design, where:

- The rotor (with coils) spins inside a stator made of permanent magnets.

- The brushes maintain electrical contact with the rotating commutator.

- As the rotor spins, the commutator reverses the current direction in the coils to maintain rotation.

Pros of DC Motors:

- Easy to control with simple ON/OFF or PWM circuits

- Ideal for battery-powered devices

- Readily available and low cost

- Simple control: DC motors can be turned on or off, and their speed adjusted using Pulse Width Modulation (PWM).

- Battery-friendly: Ideal for mobile or remote devices powered by batteries.

- Beginner-friendly: Easy to use with Arduino, Raspberry Pi, and other microcontrollers.

Cons:

- Brushes wear out over time

- Sparks and electrical noise from brush contact

- Less efficient than brushless alternatives

- Brush wear: Brushes degrade over time, leading to maintenance needs.

- Noise: Brushed DC motors can generate electrical noise and sparks.

- Limited lifespan: Due to mechanical wear.

Use Cases: Small robots, toy cars, fan projects, pumps, or any application needing continuous rotation DC motors are widely used in toys, electric shavers, robotic platforms, car window actuators, and small home appliances.

4. Types of Motors and Their Uses

Understanding the variety of motors available, each suited for specific applications. Here’s a breakdown of the most popular types in electronics and robotics will help you pick the perfect one for your task. Let’s go into more detail:

4.1 Brushed DC Motor

Brushed motors are among the oldest and most familiar motor types. They work well in low-cost applications where precision isn’t critical.

- Applications: Battery-operated toys, fans, conveyor belts, low-end hobby robots

- Design: Uses brushes and a commutator to switch current.

- Use Case: Toys, fans, simple robots.

- Strength: Cheap, simple.

- Limitation: Mechanical wear over time.

4.2 Brushless DC Motor (BLDC)

These motors eliminate brushes and use an electronic controller to switch currents in the coils. They’re more efficient, quieter, and longer lasting.

Brushless Motor (Image credit: Dcaldero8983, Wikimedia Commons, CC BY-SA 3.0)

- Applications: Drone propellers, electric bicycles, cordless tools, server cooling fans, gimbals

- Design: Electronic controller replaces brushes; uses three-phase coils.

- Use Case: Drones, RC cars, PC fans.

- Strength: Long lifespan, high efficiency, quieter operation.

- Limitation: Requires motor driver or ESC.

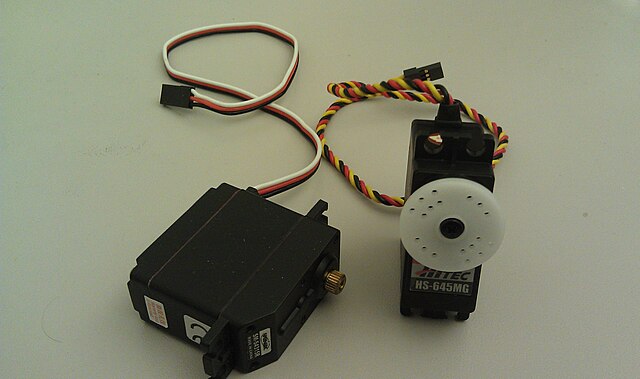

4.3 Servo Motor

Servo motors combine a DC motor with a feedback system to control position, speed, and sometimes torque. Most servo motors rotate between 0 and 180 degrees, making them ideal for controlled movements.

Applications: Robotic arms, camera pan-tilt systems, RC vehicles, automatic door locks, animatronics. built-in position control (usually 0–180°).

4.4 Stepper Motor

Stepper motors move in fixed increments or steps. This makes them great for systems where exact movement control is needed. They don’t require feedback systems and are open-loop by design.

Applications : 3D printers, CNC routers, camera sliders, telescope tracking systems

4.5 AC Motors

AC motors are used in appliances and industrial machines powered by alternating current. They are robust and capable of long-term operation in demanding conditions.

Applications: Industrial fans, washing machines, HVAC units, compressors, pumps

4.6 Linear Actuators (Linear Motors)

Linear actuators transform rotational motion into straight-line motion. They are used when pushing, pulling, lifting, or lowering something is required

Applications: Automated window systems, adjustable furniture, medical beds, industrial machinery.

5. How to Read Motor Specifications

Buying a motor without understanding the datasheet is like buying shoes without knowing your size. Here are key parameters to know:

Selecting a motor isn’t just about voltage and size. It’s about matching the motor’s electrical and mechanical specs to your application.

| Specifications | Meaning |

| Rated Voltage (V) | Ideal operating voltage range |

| Rated Current (A) | Current draw under normal load |

| Stall Current (A) | Maximum current if the motor can’t spin |

| Torque (Nm) | How strong the motor is (especially important for lifting) |

| Speed (RPM) | Rotation speed under load |

| Gear Ratio | Used in gear motors; increases torque while reducing speed |

For example, a 12V motor with 0.5Nm torque and 200 RPM might be perfect for a DIY robot’s wheels but completely unsuitable for a drone.

Reading these values ensures your power supply, motor driver, and mechanical design all align. Reading the datasheet helps you avoid mismatched components and ensures that the motor won’t overheat, stall, or damage your driver.

6. How to Choose the Right Motor for Your Project

Selecting the best motor depends on what you want it to do. Ask yourself. Choosing the right motor starts with understanding what your project needs:

Do I need speed or torque?

Fast fans or wheels → DC motors

Heavy load or lifting → Stepper or geared DC motors

If you need high-speed rotation with low complexity, a brushed DC motor is often enough.

For high-torque, precise movement, especially in automated equipment, go for a stepper motor.

Want to move something to a specific position and hold it there? Use a servo motor.

If space and efficiency are crucial (like drones), a BLDC motor is your best bet.

For sliding or lifting mechanisms, a linear actuator is ideal.

Do I need precise positioning?

Yes → Servo (limited range) or Stepper (full rotation)

No → Regular DC motor

Also, think about how you’ll control it: will you use a microcontroller? Do you need motor drivers? What kind of power supply do you have access to?

Do I have feedback/control needs?

Use encoders, servo motors, or closed-loop drivers

How am I powering it?

Battery → Choose low voltage (5V–12V)

Wall power → Use adapter and ensure safety for AC devices

Pro tip: If you’re unsure, start with a small brushed DC motor or servo. You can expand later with better drivers or motor types.

7 . Final Thoughts: Why Motors Matter

Motors are more than spinning parts — they bring your electronics to life. Whether you’re powering a simple fan or programming a six-axis robotic arm, understanding motors gives you full creative control.From the push of a sliding door to the movement of a robotic hand, motors translate code and electricity into real-world actions.

In future posts, we’ll deep-dive into specific motor types, how to wire and program them using Arduino, and how to build high-performance machines from scratchUnderstanding motors gives you the power to build, automate, and innovate. Whether you’re designing a DIY rover or working on industrial automation, mastering motor basics opens a whole world of creative possibilities.

Stay curious. Stay building. And don’t be afraid to burn out a motor or two while learning!

In future posts, we’ll explore detailed wiring guides, code examples, and full project builds using different motor types.

Stay curious. Stay building. And remember — every great invention starts with a little motion.

8. Recommended Tools and Parts (Affiliate Links)

🛠️ Whether you’re just getting started or already building DIY robots, these are the tools and parts I personally recommend. They’re beginner-friendly, affordable, and available online. I may earn a small commission if you buy through these links — at no extra cost to you!

Motor Drivers

L298N Dual H-Bridge Motor Driver

A great beginner-friendly motor driver that can handle two DC motors or one stepper.

TB6612FNG Motor Driver Module

More efficient and compact than L298N, perfect for small robots.

DC Motors & Gear Motors

6V–12V Geared DC Motor with Wheel Kit

Ideal for small robot cars and basic automation projects.

775 High-Torque DC Motor

For higher load tasks like drills, CNCs, and heavy-duty bots.

Servo Motors

SG90 Micro Servo Motor (Pack of 5)

Great for pan-tilt systems, robot arms, and basic servo control.

MG996R High Torque Servo

Best for robotic arms or any application needing more force.

Stepper Motors

28BYJ-48 Stepper Motor + ULN2003 Driver Board

Beginner-friendly and cheap. Best for slow, controlled motion.

NEMA 17 Stepper

Perfect for 3D printers and CNC projects.

Power Supply & Accessories

12V 2A Power Adapter with DC Jack

Powers your motor drivers reliably and safely.

Male-to-Male Jumper Wires (40 pcs)

You’ll need these for breadboard and motor connections.

Screw Terminal Shield for Arduino Uno

Makes wiring cleaner and stronger when connecting motors.

👉Pro Tip: Always double-check voltage, current, and torque requirements before buying motors. Underrated power = weak motor. Overrated power = fried circuits.

10. Frequently Asked Questions (FAQ)

Q1: What’s the difference between a servo motor and a stepper motor?

A servo motor is designed for precise angle control. It moves to a specific position based on a control signal and usually has a feedback mechanism to correct its movement. That’s why servo motors are perfect for applications like robotic arms, camera gimbals, and pan-tilt systems.

A stepper motor, on the other hand, rotates in fixed steps. It doesn’t need feedback to know its position (in most cases), which makes it great for 3D printers, CNC machines, and any task where repeatable movements are needed.

| Feature | Servo Motor | Stepper Motor |

| Control | Position via PWM | Steps via driver pulses |

| Feedback | Usually has feedback | Open-loop (usually) |

| Common Use | RC, Robotics | 3D Printer, CNC |

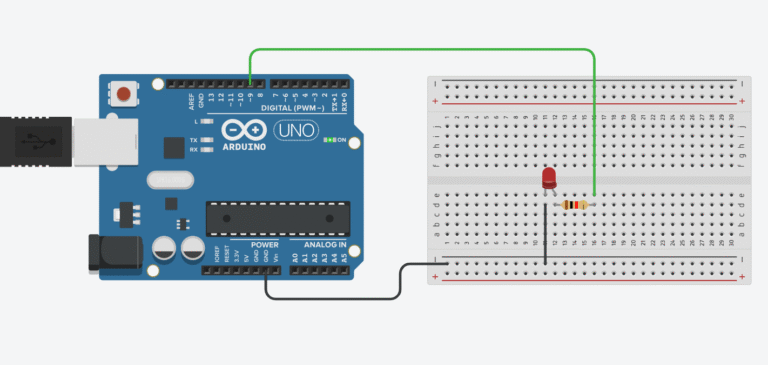

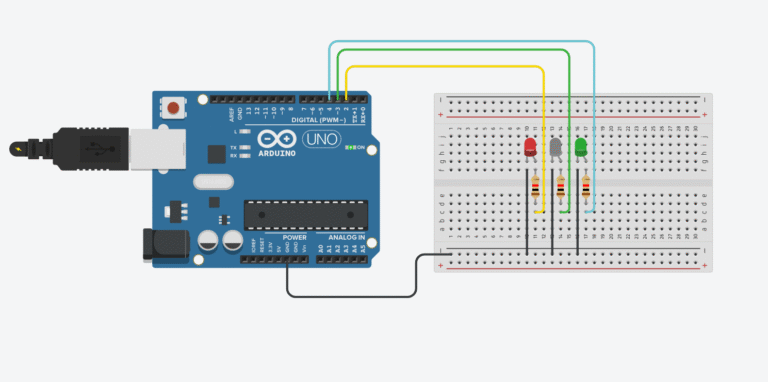

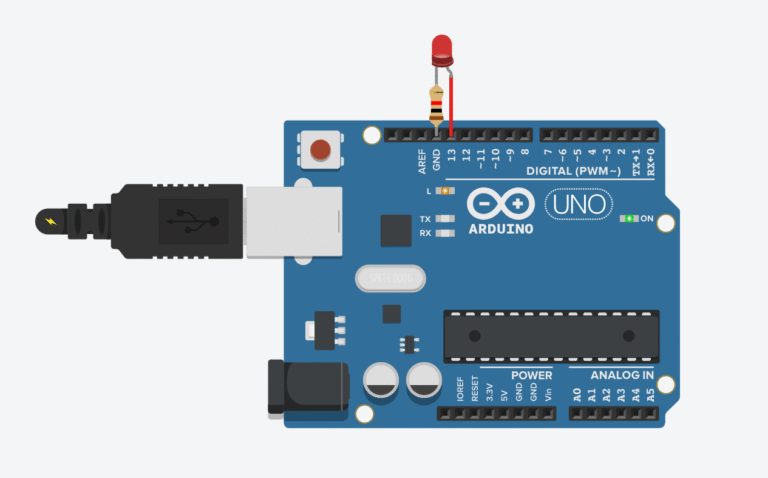

Q2: Can I power a motor directly from an Arduino?

Small motors like the SG90 micro servo can be powered directly from the 5V pin of the Arduino if only one is used. However, DC motors and stepper motors draw more current than an Arduino can safely provide. For those, you should always use an external power source (like a battery pack or power adapter) and a motor driver (such as L298N, TB6612, or A4988) to control the motor safely.

Tip: If your Arduino keeps resetting when the motor runs, it’s a sign you need external power.

Q3: Why is my motor getting hot or making noise?

There are a few possible causes:

You’re running the motor at a higher voltage than it’s rated for.

The motor is under too much load or friction, causing it to overwork.

You might be stalling the motor (trying to stop it while it’s running).

In brushed motors, worn brushes or sparks can cause heat and noise.

Always check the motor’s rated voltage and current before powering it.

Q4: What motor should I use for a small robot car?

For simple two-wheeled robots, a pair of 6V–12V geared DC motors is a popular choice. They provide a good balance between speed and torque. Combine them with an L298N or TB6612 motor driver, and you’re good to go.

If you need more precision (like turning exact angles), go for stepper motors. And if you need quick turning with position feedback (like a robotic arm), use servo motors.

Q5: Where can I buy good-quality motors for DIY projects?

Some trusted online platforms include:

Amazon – Fast shipping, wide range, and user reviews

Adafruit – Great for Arduino-based projects

SparkFun – DIY-focused kits and motors

DFRobot – Reliable supplier for robotics parts

AliExpress – Cheap, but check seller ratings

When buying, always check voltage rating, torque, and shaft size to match your project needs.