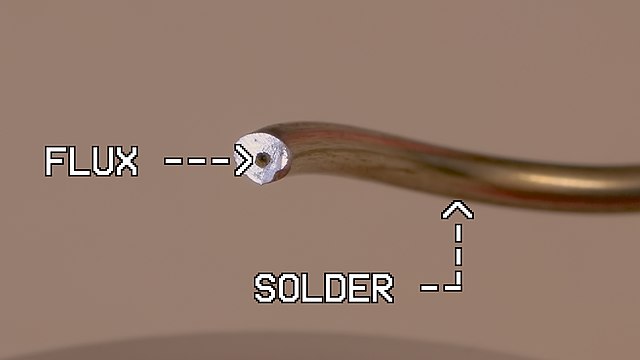

When you’re soldering electronics, choosing the right flux might not seem important at first—but trust me, it can make or break your entire project. Flux helps clean metal surfaces and allows solder to stick properly, ensuring strong, reliable joints.

It removes oxidation, improves wetting, and prevents metal from re-oxidizing during soldering. Basically, flux is your silent helper, making sure everything bonds the way it should.

Let’s break down the types of flux and figure out which one fits your DIY electronics project best.

New to soldering? You might also like: Essential Soldering Tools for Beginners

This page includes affiliate links. I may earn a small commission if you purchase through them – at no extra cost to you.

Types of Flux You Should Know

1. Flux-Core Solder Wire

The easiest and most beginner-friendly way to apply flux is by using flux-core solder wire. This type of solder wire already has flux inside it, usually about 1–3%. When you melt the solder, the flux is automatically released to clean and prepare the surface for proper soldering.

If you find your flux-core solder wire isn’t doing the trick, it’s usually because your component leads or PCB pads are heavily oxidized. In these cases, you should add extra flux separately. Just make sure you match it correctly:

- For No-Clean core, use No-Clean flux separately.

- For Rosin-core, use Rosin flux separately.

Curious about solder itself? Forms of Solder Explained

2. Flux Paste

Flux paste has a thick consistency and is perfect for surface-mount (SMD) components or precision soldering jobs. You can apply it with a brush, toothpick, or syringe to control exactly how much and where you place it.

Flux paste makes soldering easier by holding components in place and allowing solder to flow smoothly. Ideal when soldering tiny, tricky components.

3. Liquid Flux

Liquid flux is great for precise application on solder joints. It’s commonly applied using a cotton swab, small brush, pipette, or syringe. This type of flux is very versatile for general-purpose electronics work.

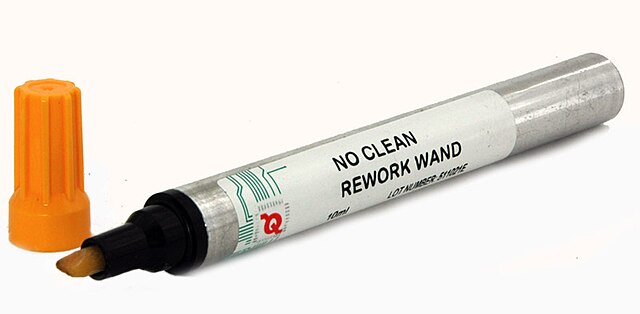

4. Flux Pens

Flux pens are essentially liquid flux in a convenient pen form. They’re simple and handy for quickly applying flux exactly where needed without mess or waste. Ideal for quick jobs or small touch-ups on your circuit.

Flux Classifications

Flux generally comes in two classifications: Organic (used for electronics) and Inorganic (used for plumbing or industrial applications).

Organic Fluxes

No-Clean Flux

- The least aggressive and easiest type of flux to use.

- Does NOT require cleaning after soldering.

- Perfect for newer, less oxidized components or PCBs.

Rosin Flux

- Most common flux, extracted from pine resin.

- Comes in three levels:

- R (Non-Activated Rosin): Least aggressive; suitable for already clean metals.

- RMA (Rosin Mildly Activated): More active, cleans moderate oxidation, leaves minimal residue.

- RA (Rosin Activated): Strongest of Rosin fluxes, removes heavy oxidation but leaves significant residue needing cleaning.

Important note:

- Some Rosin fluxes are labeled as “No-Clean,” but not all Rosin fluxes fall under this category. Always double-check the label.

Inorganic Fluxes

- Usually acid-based, intended for plumbing or industrial uses.

- NEVER use this type on electronics, as it’ll corrode your board.

Water-Soluble Flux

Water-soluble flux is super aggressive at cleaning oxidation. The residues from this flux must be thoroughly rinsed off with water after soldering, as they can cause severe corrosion if left on the board.

Important tips for Water-Soluble Flux:

- Always wash thoroughly with distilled or DI water.

- Use isopropyl alcohol afterward to remove any remaining moisture.

- Completely dry the board before powering it up again.

Only use water-soluble flux as a last resort when other flux types fail to clean heavily oxidized parts.

Final Thoughts

Choosing the right flux isn’t complicated once you understand the basics. Here’s a quick recap:

- For beginner-friendly, general-purpose soldering: Flux-core solder wire (rosin or no-clean).

- For precision SMD jobs or reworking tiny components: Flux paste or flux pen.

- For tough oxidation cases: RA Rosin Flux or Water-Soluble Flux (with proper cleaning).

Flux isn’t flashy, but it’s your best friend when soldering. Pick the right one, and you’ll save yourself a ton of headaches down the road.

Happy soldering!

❓ FAQ – Flux Usage, Storage, and Buying Tips

Q1: Do I need to clean flux residue after soldering?

- No-clean flux: Usually not—unless you’re dealing with sensitive analog or RF circuits where even slight residue might affect performance.

- Rosin flux (RMA, RA): Yes. Use isopropyl alcohol (IPA) and a soft brush.

- Water-soluble flux: Always clean. Rinse thoroughly with distilled water, then follow with IPA.

Q2: Can I use plumbing flux for electronics?

A: No. Nope. Never.

Plumbing flux is acidic, meant for copper pipes. It will corrode your PCB, damage components, and possibly kill your whole circuit. Stick to electronics-safe flux only.

Q3: How do I know which flux to buy?

- For general work (Arduino, small projects): Flux-core wire + no-clean or RMA liquid flux

- For SMD or precision soldering: Flux paste or pen

- For oxidized or dirty surfaces: RA Rosin or water-soluble flux

Q4: Is flux toxic or dangerous?

- Rosin-based flux can give off fumes that irritate eyes and lungs if used in unventilated areas.

- Always solder in a well-ventilated space. Better yet, get a small fume extractor.

👉 Portable fume extractor for safe soldering at home.

Q5: Can I mix different types of flux?

A:

You technically can, but it’s not recommended. Some fluxes leave residue that others can’t clean, or they might react chemically. Best practice: stick with one type throughout your project.