When you’re starting any soldering project, choosing the right combination of solder and flux is one of the most important steps.

Solder comes in several forms depending on your tools and use case. Let’s go through the most common ones, especially if you’re a DIY electronics hobbyist.

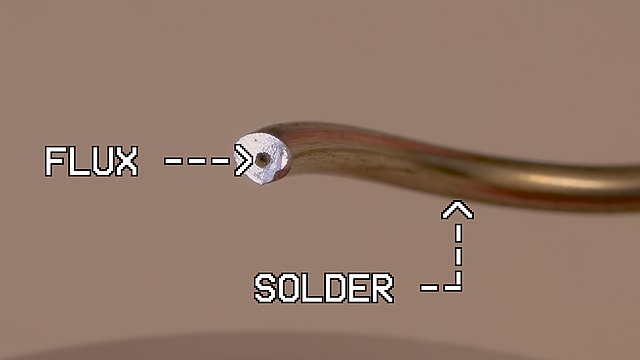

If you’re working with electronics and a soldering iron, then flux-core solder wire is your best friend.

New to soldering? Start with our guide: Essential Soldering Tools for Beginners

Solder Wire

This is the most beginner-friendly form. It usually comes in a spool or a tube, and is available in both solid and flux-core versions.

Most electronics folks (including me) use flux-core solder wire because it makes things easier, faster, and less messy.

Recommended for: General soldering, Arduino, PCBs

👉 Check this top-rated flux-core solder wire

Also read: What Is Flux in Soldering? A Beginner’s Guide to Cleaner, Stronger Joints

Solder Paste

A paste that combines solder and flux, often packaged in syringes. This stuff is great for surface-mount (SMD) components, where you apply it to pads and then heat everything up in a reflow process.

Recommended for: SMD work, reflow soldering

👉 Try this beginner-friendly solder paste

This page includes affiliate links. I may earn a small commission if you purchase through them – at no extra cost to you.

Solder Bars

These are large chunks of solder—more for industrial use, like in solder pots or wave soldering setups. You probably won’t need this unless you’re running a factory in your garage.

Recommended for: High-volume manufacturing

Solder Preforms

Think tiny discs or washers made of solder—precision-engineered for specific applications. These are typically used in automated production lines where everything has to be exact.

Recommended for: High-reliability or automated systems

⚪ Solder Spheres (Balls)

Used for BGA chips, solder spheres are tiny balls of solder placed using stencils. If you’re playing with BGA rework… you’re already a pro.

Recommended for: BGA repair, reballing

Leaded vs Lead-Free Solder Alloys – Which One Should You Use?

Leaded Solder (60/40 & 63/37)

Traditional solder is made from a mix of tin (Sn) and lead (Pb), with 60/40 and 63/37 being the most common ratios. These alloys are known for their low melting points and excellent wetting properties, making them easy to use—especially for electronics.

When soldering, the alloy needs to reach a fully liquid state for proper wetting. If the temperature is too low, the solder may only reach the plastic state (the phase between solid and liquid), which can result in a weak or unreliable connection.

Among the two, 63/37 is a eutectic alloy, meaning it melts and solidifies at the same temperature—no in-between state—making it ideal for electronics. 60/40 offers a shinier finish but requires more temperature control.

For most electronics work, 63/37 is highly recommended.

Lead-Free Solder & RoHS Compliance

Due to environmental and health concerns, many regions now restrict leaded materials through regulations like RoHS (Restriction of Hazardous Substances).

In case you didn’t know, RoHS is an EU directive that bans the use of lead and other toxic materials in electronics sold within its member countries. As a result, most modern consumer electronics are now built using lead-free solder.

You’ve probably seen the RoHS symbol on devices like iPhones, TVs, or even your laptop—yep, that little label means it’s compliant. In other words, all the components inside were soldered using lead-free alloys.

Popular lead-free alloys include:

- SAC305 (96.5% Tin / 3% Silver / 0.5% Copper)

- 96/4 (96.5% Tin / 3.5% Silver)

Although lead-free solder requires higher melting temperatures and offers slightly weaker wetting, it’s the standard for RoHS-compliant manufacturing. SAC305 is widely recommended for its performance and reliability.

So, Which One Should You Use?

- Use leaded solder (63/37) for hobby projects or repairing older, non-RoHS devices—it’s easier and more forgiving.

- Use Lead-free solder (SAC305) for anything modern, commercial, or RoHS-compliant.

❓ FAQ – Solder Buying & Usage Tips

Q: What flux-core size should I buy?

A: For most Arduino/PCB projects, go with 0.6mm to 0.8mm diameter. It gives you enough control without flooding the pads.

Q: Do I need separate flux if I already use flux-core wire?

A: Not always, but extra flux helps when joints are stubborn or pads are oxidized. I recommend keeping a small no-clean flux pen handy.

👉 This flux pen saved my butt many times

Q: Why does my solder look dull or grainy?

A: That’s often due to cold joints. Make sure your tip is hot enough (around 300–350°C) and that both surfaces are heated evenly.

Q: Can I mix leaded and lead-free solder?

A: Technically yes, but not recommended. It creates unpredictable melting points and weakens joints. Stick with one type throughout your project.