What is a DC Motor?

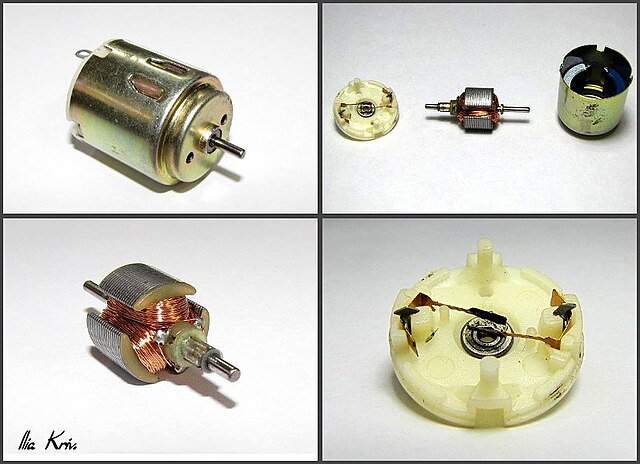

A DC motor is a type of electric motor that operates using direct current (DC) as its power source to generate mechanical force or motion. The most commonly used DC motors function by utilizing magnetic fields created by the electric current flowing through the coils. Almost all DC motors incorporate an internal switching mechanism — either electromechanical, like a commutator and brushes, or electronic, such as a motor controller — to regularly reverse the direction of the current in certain windings. This reversal is what enables continuous rotation of the motor shaft.

How Does a DC Motor Work?

When an electric current flows through a coil of wire, it creates an electromagnetic field that is aligned along the center axis of the coil. The direction and strength of this magnetic field can be controlled by adjusting the direction and magnitude of the current flowing through the wire. This principle is the core foundation of how DC motors operate.

In a basic DC motor, the stator (the stationary part) contains a set of permanent magnets (or electromagnets in some designs), while the rotor, also known as the armature, is equipped with one or more windings of insulated wire wrapped around a soft iron core. This core helps concentrate the magnetic field generated by the coil. These windings usually consist of multiple turns, and in larger motors, there may be several parallel current paths to handle higher power.

The ends of the wire winding are connected to a commutator, which is a mechanical switch that sequentially energizes each armature coil. The commutator, working in tandem with carbon brushes, transfers electric current from the external power supply to the spinning rotor, while also periodically reversing the current direction to maintain continuous rotation.

(Note: In brushless DC motors, this commutation is handled electronically using sensors and controllers, eliminating the need for brushes and a physical commutator.)

Brushed DC Motors

A brushed DC motor operates by transforming direct current (DC) electricity into mechanical motion through a process called internal commutation. Inside this type of motor, stationary magnetic fields—either created by permanent magnets or electromagnets—interact with rotating electromagnets located on the rotor. This interaction produces torque, which causes the motor shaft to spin. The commutator, a rotating switch connected to the motor’s shaft, works together with brushes to deliver current to the right coil at the right time, ensuring continuous rotation by reversing current flow through the rotor windings as needed.

One of the major benefits of brushed DC motors is their simplicity. They have a relatively low manufacturing cost and are easy to control using basic circuitry. Because they respond well to simple voltage variations, they are often used in systems that require direct and easy speed or torque adjustment. These characteristics make them ideal for entry-level applications, educational kits, or basic automation setups. In many consumer electronics and power tools, brushed DC motors are still widely used because of their affordability and ease of integration.

However, this simplicity comes with trade-offs. The physical contact between the brushes and the commutator leads to mechanical wear over time. This results in the need for regular maintenance, which typically involves replacing worn-out carbon brushes, checking spring tension, and cleaning or resurfacing the commutator to prevent arcing or loss of performance. In high-load or continuous-use applications, this wear becomes more significant and can shorten the motor’s lifespan if not properly addressed.

The brushes themselves are made of conductive materials—commonly carbon or graphite. These materials are soft enough to wear gradually against the rotating commutator while still conducting electricity. In some cases, copper is added to the brushes to enhance conductivity. As the brushes wear down, a spring-loaded mechanism keeps them pressed firmly against the commutator to maintain electrical contact. For higher current applications, the brushes often include embedded wires (flying leads) that connect directly to the motor terminals to carry larger electrical loads safely.

In miniature brushed motors, such as those found in toys or disposable electronics, the brush design is much simpler. These may rely on direct sliding contact with a metallic holder or spring-loaded metal strips rather than complex brush assemblies. While cost-effective, these designs are only suitable for short-term or low-duty applications and are not intended for long-term durability.

Despite their maintenance needs, brushed motors continue to play an important role in applications where simplicity, low cost, and easy control are more critical than long-term durability or efficiency. You’ll find them in everything from electric toothbrushes and RC cars to automotive actuators and basic conveyor systems. Their ease of use, combined with predictable performance, ensures they remain a staple in both hobbyist and industrial spaces.

Brushless DC Motors

How Brushless Motors Work

Brushless DC motors, often abbreviated as BLDC motors, represent a modern evolution of the traditional brushed DC motor. Unlike their brushed counterparts, brushless motors do not use physical brushes or a commutator to switch current in the windings. Instead, electronic circuits, often called motor controllers, handle the task of commutation. This design eliminates one of the most common sources of mechanical wear in traditional motors, significantly improving durability and reducing the need for routine maintenance.

The construction of a typical brushless DC motor includes one or more permanent magnets attached to the rotor and a series of electromagnets fixed to the stator (the outer casing of the motor). When the motor is in operation, the controller precisely energizes the stator coils in a sequence that causes the rotor to rotate. This sequence is determined based on the rotor’s position, which is often detected using Hall effect sensors or similar feedback devices. These sensors monitor the exact location of the rotor and ensure that the stator coils are energized at precisely the right time to maintain smooth and efficient rotation.

Because brushless motors lack physical contact between moving electrical components, they generate far less electrical noise and are more efficient than brushed motors. The elimination of friction caused by brush-commutator contact not only increases lifespan but also reduces energy losses in the form of heat. These advantages make brushless motors the preferred choice in applications where efficiency, longevity, and reliability are crucial.

However, brushless motors do come with a higher initial cost, primarily due to the complexity of their electronic controllers. Designing and manufacturing these controllers requires additional circuitry, often involving microcontrollers, power transistors, and precision timing components. This can be a barrier in budget-sensitive projects, especially when simple control systems are sufficient.

One noteworthy aspect of brushless motors is their regenerative braking capability when used in appropriate systems. Just like brushed motors, when external mechanical force is applied to a brushless DC motor, it can act as a generator. This functionality is widely used in electric vehicles and hybrid cars to recover energy during braking, converting kinetic energy back into electrical energy and storing it in the battery.

In summary, brushless DC motors offer a compelling alternative to traditional brushed motors when longevity, energy efficiency, and precision control are prioritized. Their only real downside—higher initial cost and control complexity—is increasingly mitigated by the availability of affordable motor controllers and advanced firmware, making them more accessible than ever for both industrial and DIY applications.

Other Specialized DC Motors

Homopolar Motors

Not all DC motors rely on traditional commutation methods. Some unique types of DC motors function without the need for switching current direction through brushes or electronics. These motors are often used for specialized applications or as educational demonstrations due to their unconventional operating principles.

One such example is the homopolar motor. This motor operates with a magnetic field aligned along the axis of rotation, and an electric current that flows in a direction that is, at some point, not parallel to this magnetic field. The term “homopolar” refers to the fact that there is no change in polarity during operation. Structurally, homopolar motors are extremely simple and typically use a single-turn coil, which inherently limits the operating voltage and, consequently, the motor’s power output. Because of this limitation, homopolar motors are mostly restricted to low-voltage applications and are not commonly found in practical use. They are, however, popular in educational settings due to their simplicity and visual demonstration of electromagnetic principles.

Ball Bearing Motors

Another unconventional design is the ball bearing motor. Unlike typical motors, this type consists of two ball bearings — essentially acting as both mechanical support and electrical conductors. In this setup, the inner races of the bearings are mounted on a shared conductive shaft, while the outer races are connected to a high-current, low-voltage power source. There’s also an alternate design where the outer races are housed within a metal tube, and the inner races are fitted onto a shaft with an insulating section, such as two sleeves on an insulating rod. This tube not only helps with mechanical alignment but also acts as a flywheel, storing rotational energy. Interestingly, this motor doesn’t have a defined direction of rotation — it usually needs a manual push or spin to get started. The initial spin determines the rotation direction, as there’s no magnetic polarity to guide it inherently. Ball bearing motors are more of a physics curiosity than an industrial tool, but they demonstrate some fascinating electromagnetic effects.

Permanent Magnet DC Motors

Lastly, DC motors with permanent magnet (PM) stators represent a more conventional and widely used class of motors. Instead of using wound coils to generate a magnetic field in the stator, these motors use permanent magnets. These magnets provide a constant magnetic field that the rotor’s electromagnetic field interacts with to produce torque. While this design eliminates the need for energy to power field windings, it also means that the magnetic field is fixed — making speed control more difficult compared to motors with adjustable field windings.

To improve commutation under load, some larger PM motors incorporate compensation windings in series with the armature. These windings help stabilize the operation when the motor is under heavy torque demands. Historically, permanent magnets were not favored in larger motors because they could lose magnetism if disassembled or exposed to high temperatures. As a result, field windings were more practical for generating strong, controllable magnetic fields. However, advancements in materials science have led to the development of high-energy magnets, such as neodymium-iron-boron (NdFeB), which retain strong magnetic fields even under demanding conditions. These magnets are now widely used in small but powerful PM motors.

In miniature applications, using PM stators has several advantages. They reduce the size and weight of the motor and eliminate power consumption associated with field coils. This makes them ideal for battery-powered devices such as drones, RC cars, and small robotic systems. These miniature motors typically feature at least three poles in the rotor to ensure reliable startup from any position. Structurally, they often have a steel tube outer housing, which serves to link the external parts of the curved field magnets magnetically and provide a compact and efficient magnetic circuit.

DC Motor FAQs

- What is the main difference between brushed and brushless DC motors? Brushed motors use carbon brushes and a mechanical commutator to switch current, while brushless motors rely on electronic controllers to perform the same function. Brushless motors tend to be more efficient, require less maintenance, and have a longer lifespan.

- Are DC motors still used today despite the rise of AC motors? Absolutely. DC motors are widely used in applications where variable speed control and high torque at low RPM are needed — such as electric vehicles, robotics, elevators, and power tools.

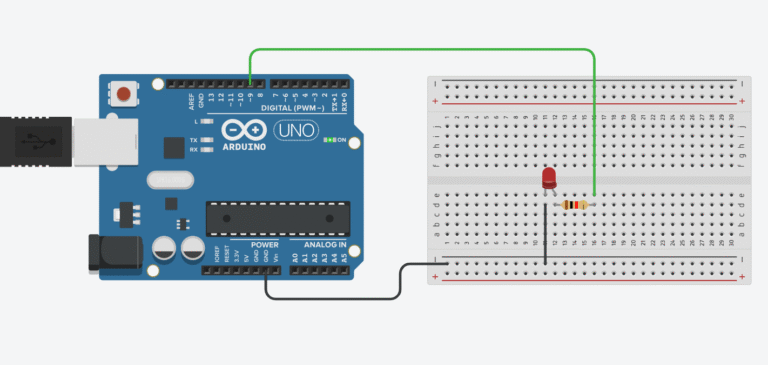

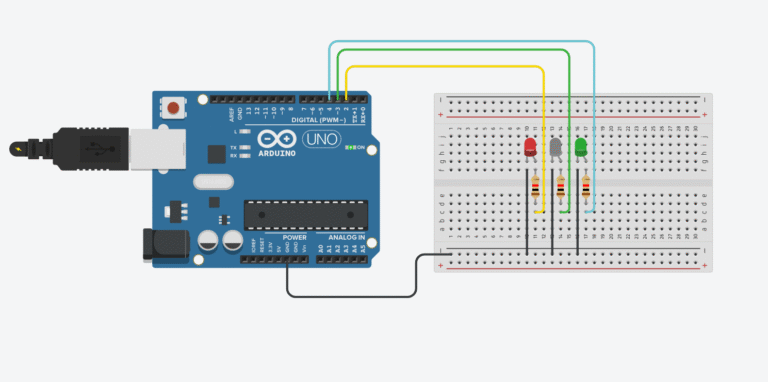

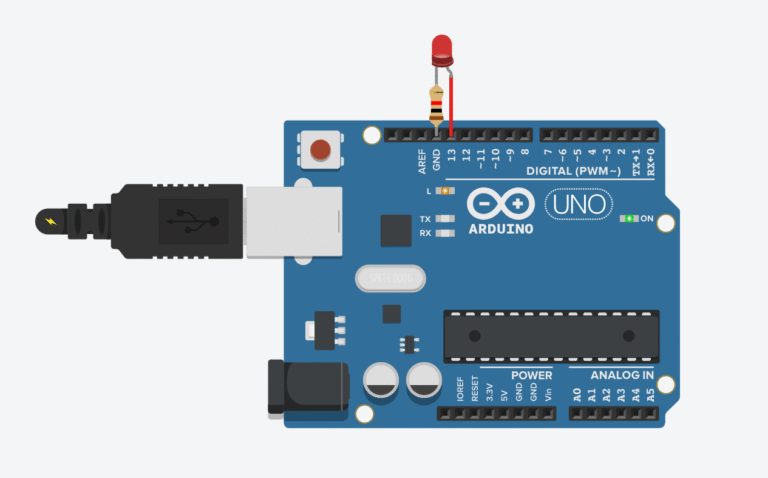

- Can I control the speed of a DC motor without a microcontroller? Yes, by using variable resistors (rheostats) or simple motor drivers with manual potentiometers. However, for more precise and programmable control, using a microcontroller like an Arduino is highly recommended.

- Which type of DC motor is best for my project? It depends on your requirements. For simple, low-cost applications, a brushed DC motor may be ideal. If you need high performance, long life, and low noise, a brushless DC motor is the better option.

- What power source should I use for small DC motors? Small DC motors typically run on 3V to 12V, and can be powered using batteries, regulated power supplies, or even USB if the current draw is low enough.

- Are permanent magnet DC motors better than wound field motors? PM motors are more compact and energy-efficient for small-scale uses, but wound field motors offer better speed control and are more suitable for high-power industrial applications.

Best Tools and Kits for DC Motor Projects

Here are some handpicked DC motor kits and accessories I’ve personally used or reviewed — perfect for beginners, hobbyists, and students:

- DC Motor + Gearbox Combo for Arduino Projects (Amazon)

- L298N Motor Driver Module – Dual H-Bridge Controller (Amazon)

- 12V Power Supply Adapter for Robotics Projects (Amazon)

- Basic DIY Electronics Starter Kit (Amazon)

- Super Starter Kit Based on Arduino UNO R3

These are affiliate links. If you make a purchase through them, I may earn a small commission at no extra cost to you. It helps support this blog and allows me to keep creating free content. Thank you!

Final Tip: Why DC Motors Are a Must-Know for Makers

If you’re diving into robotics, DIY electronics, or just curious about how motors work, learning DC motor fundamentals is a powerful foundation. Bookmark this post and explore more tutorials on this blog — from hands-on Arduino guides to full robot builds!