Introduction to Brushed DC Motors

Brushed DC motors are one of the most fundamental and widely used types of electric motors in the world. Their simplicity, low cost, and straightforward operation make them a favorite in everything from toys and household appliances to industrial machines and automotive systems. Despite the rise of brushless and AC motors, brushed DC motors continue to offer advantages in specific use cases where ease of control and immediate torque response are more valuable than long-term efficiency.

History and Evolution of Brushed Motors

Brushed motors were the first commercially important application of electric power to drive mechanical energy. For over a century, DC distribution systems powered these motors in commercial and industrial buildings, playing a critical role in automation and infrastructure development. Their speed can be controlled by adjusting the voltage or modifying the strength of the magnetic field. Based on how the field windings are connected to the power supply, brushed motors can deliver a steady rotational speed or a speed that inversely follows the mechanical load. Because of this flexibility, they are still found in applications like electric propulsion systems, cranes, paper machines, and steel rolling mills.

However, these motors also have known weaknesses. When current passes through the coil wrapped around a soft iron core within an external magnetic field, the resulting forces cause a rotational motion, as explained by Fleming’s left-hand rule. In a basic two-pole motor design, torque drops to zero when the plane of the coil becomes parallel to the magnetic field. At this zero-torque position, the motor may fail to start unless nudged. Additionally, a short-circuit problem can occur when both commutator brushes simultaneously contact both commutator segments. This condition can cause overheating, wasted energy, and damage to the commutator or brushes.

To address this, one solution is to widen the gap between commutator plates so that brushes do not bridge them simultaneously. While this avoids shorting, it also increases the range of zero-torque positions and causes pulsed torque output, making it unsuitable for precision applications. Moreover, inductance in the coils causes arcing as current attempts to bridge the gap, further complicating design and reducing longevity.

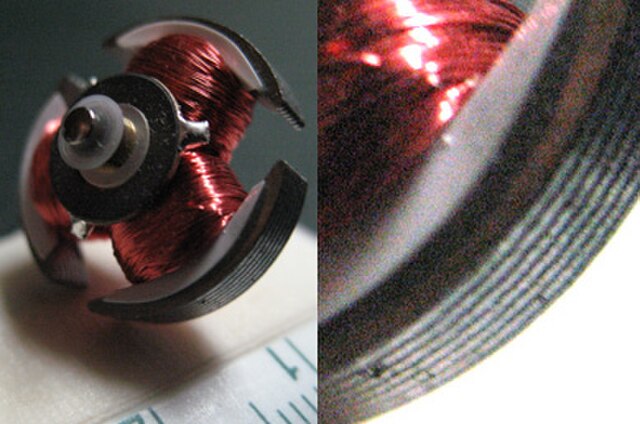

For practical motors, these issues are overcome by using designs with more than two poles. Most small brushed DC motors today feature three-pole armatures. These prevent short circuits when brushes bridge commutator segments and ensure that the motor can start from any position. The current flowing through the coils in these designs more closely mimics a sinusoidal waveform, leading to smoother torque delivery and reduced arcing. This refinement has helped make three-pole brushed motors the default for many commercial uses like toys, small appliances, and hobbyist projects.

How Do Brushed DC Motors Work?

At the core of a brushed DC motor are two key magnetic fields: one generated by the stator (either permanent magnets or electromagnets) and one generated by the rotor, or armature, through wound copper coils. The interaction between these fields is what produces torque. The commutator and brushes are what set brushed motors apart. The commutator is a segmented ring attached to the motor’s shaft, and carbon or graphite brushes maintain contact with it. As the shaft spins, the commutator reverses the direction of current in the rotor windings, ensuring continuous rotation. This process is known as mechanical commutation.

A typical brushed DC motor includes several key parts. The stator provides a stationary magnetic field and can either be made of permanent magnets or wound field coils. The rotor, also called the armature, is a rotating shaft that has copper coils wound around a laminated iron core. The commutator is a segmented copper ring that switches the current direction in the rotor windings, while the brushes are conductive blocks—usually made of carbon—that press against the commutator to transfer electricity. Bearings support the rotor and reduce friction, and the housing encloses and protects all internal parts. Each component has a crucial function, and together they enable the motor to convert electrical energy into mechanical motion.

Advantages and Disadvantages

Brushed motors are incredibly easy to control. Applying voltage directly allows the motor to start spinning without complex electronics. They provide immediate torque from a standstill, making them excellent for applications that require high torque at low speeds. They are also relatively inexpensive to manufacture and repair, which keeps the overall system cost down. Their design is widely understood, and they are available in many different sizes, voltages, and torque ratings.

DC motor pole lamilation (Image credit: by DMahalko, Wikimedia Commons, CC BY-SA 3.0)

Despite their strengths, brushed motors come with some drawbacks. The most significant issue is mechanical wear. Because the brushes are in constant contact with the commutator, both components degrade over time. This wear leads to the generation of electrical arcs or sparking, which can produce electromagnetic interference and additional wear. As a result, brushed motors require periodic maintenance, such as brush replacement and commutator cleaning. They also tend to have lower efficiency compared to brushless designs due to friction and heat losses.

Maintenance Tips for Longevity

To ensure a brushed DC motor lasts as long as possible, regular maintenance is key. Cleaning the commutator with a soft brush or alcohol wipe helps remove debris and buildup. Brushes should be checked and replaced before they wear down completely, as overly worn brushes can damage the commutator. Avoiding overloading conditions can reduce excessive heat, which in turn extends motor life. Any unusual noise or vibration may indicate a worn brush or bearing and should be addressed promptly. Compared to brushless motors, brushed DC motors are noisier due to the friction between brushes and the commutator.

Best Brushed DC Motor Kits and Tools

If you’re getting started with brushed DC motors or building small robotics and automation projects, here are some reliable tools I recommend (affiliate links):

High-Torque Brushed DC Motor 6V–12V (Amazon) – great for Arduino, cars, and small mechs.

L298N Dual H-Bridge Motor Driver Module (Amazon) – perfect for controlling two DC motors or a small robot.

12V Regulated Power Supply Adapter (Amazon) – stable power source for lab and test bench setups.

Brush Replacement Kit for DC Motors (Amazon) – universal carbon brushes for small maintenance jobs.

Disclosure: These are affiliate links. If you make a purchase through them, I may earn a small commission at no extra cost to you. It helps support this blog and keeps the free content coming.

Frequently Asked Questions (FAQ)

Q1: What’s the main difference between brushed and brushless DC motors?

Brushed motors use mechanical commutation through brushes and a commutator, while brushless motors use electronic commutation, leading to longer lifespans and quieter operation for brushless motors.

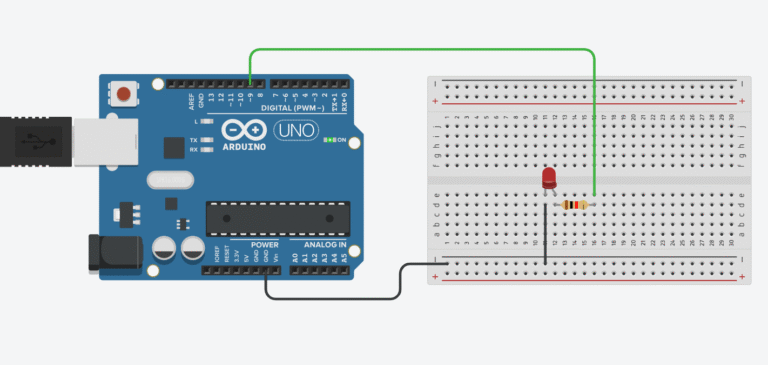

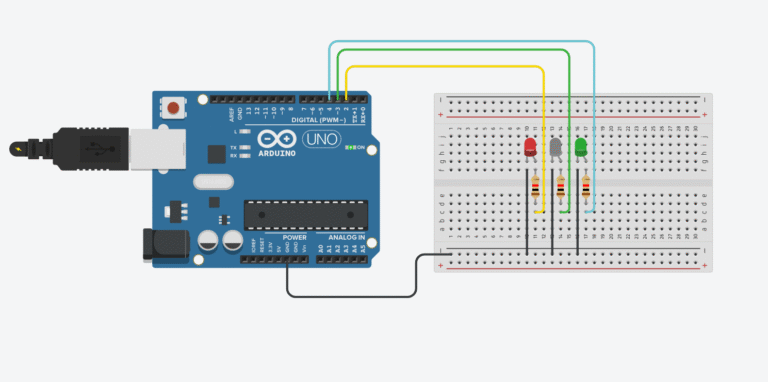

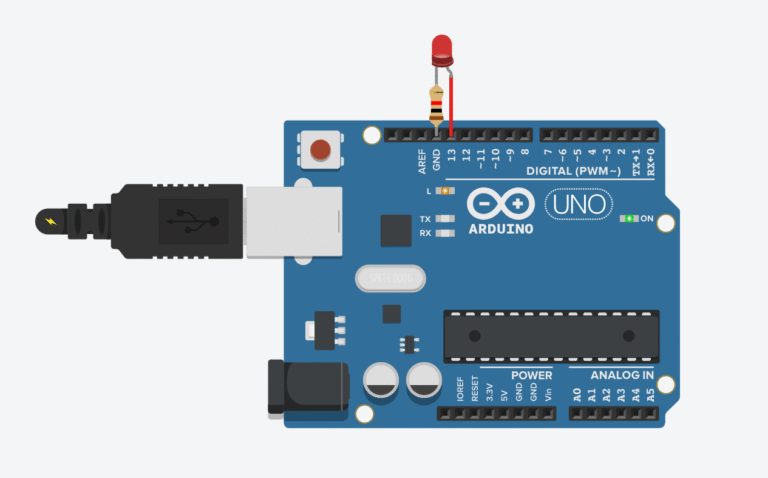

Q2: Can brushed motors be controlled with Arduino?

Absolutely! Modules like the L298N simplify controlling brushed DC motors with PWM signals for speed and digital pins for direction.

Q3: What voltage do brushed motors typically run on?

Most hobbyist and consumer-grade motors run on 3V–24V. Industrial models often use much higher voltages depending on application demands.

Q4: Are brushed motors suitable for continuous operation?

Yes, with adequate cooling and proper maintenance. Ensuring good ventilation and regular check-ups significantly extends their operational lifespan.

Q5: Are brushed DC motors noisy?

Yes, they generate both mechanical and electrical noise due to the friction between the brushes and the commutator.

Conclusion: Should You Still Use Brushed DC Motors?

Brushed DC motors may be considered a legacy technology, but they’re still going strong for a reason. Their ease of use, affordability, and flexibility make them ideal for prototyping, learning, and budget-sensitive applications. Whether you’re just starting out in electronics or need a quick, reliable motor for a test setup, brushed motors provide a simple yet effective solution. As we continue exploring motor technologies, understanding the brushed motor is a solid foundation for diving into more advanced systems like brushless DC motors in the next article.

If you found this guide helpful, check out our other motor tutorials or subscribe to the newsletter to get updates on robotics, Arduino, and electronics DIY projects!