Potentiometers — commonly known as “pots” — are essential building blocks in modern electronics and electrical engineering. These adaptable components serve as a bridge between electrical signals and the physical controls we interact with, enabling smooth adjustments of voltage, current, or signal levels across countless systems. Whether it’s tweaking audio volume, calibrating sensors, or setting motor speeds in robotics, potentiometers provide an intuitive, precise way to manage electronic behavior.

In this guide, we’ll take a deep dive into potentiometers — starting with the core principles behind how they function, followed by their construction and internal mechanism. We’ll explore the major types of potentiometers and clarify how they differ from similar components like rheostats and encoders. Finally, we’ll break down key design specs and considerations to help you choose the right potentiometer for your next project.

What is a Potentiometer?

Resistors provide a fixed value of resistance that blocks or resists the flow of electrical current around a circuit, and they produce a voltage drop in accordance with Ohm’s law. These resistors can be manufactured with a fixed resistance in Ohms, or they can be designed to vary resistance — and that’s where the potentiometer comes in.

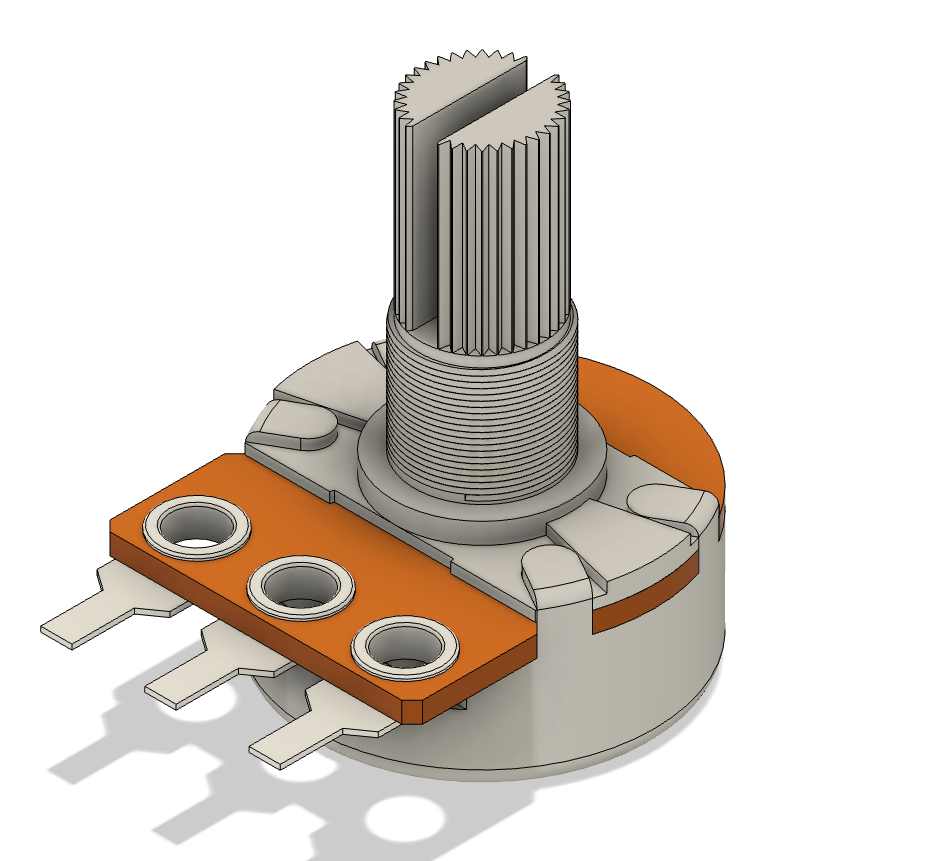

A potentiometer, often called a “pot,” is a three-terminal analog device that adjusts resistance using a mechanical input. It’s commonly used in countless electronic circuits. Importantly, it is a passive device, meaning it doesn’t need a power source or extra components to function as a variable resistor or voltage divider.

How Potentiometers Work

Unlike static resistors, potentiometers allow for manual adjustment of electrical properties like voltage or current. This makes them incredibly useful for applications like adjusting audio volume, tuning instruments, or calibrating sensors. When precise tuning is needed — for example, in setting a circuit to a zero point — potentiometers are indispensable.

The term “potentiometer” originates from “potential difference” and “metering,” reflecting its original use as a tool to control and measure voltage. Historically, large wire wound coils were used to adjust potential difference manually, but modern potentiometers are far more compact, accurate, and versatile.

These devices go by many names — variable resistor, preset, trimmer, rheostat — depending on their configuration and use case. Despite the variety of names, the core functionality remains the same: a changeable resistance value controlled by physically moving a contact (or wiper) across a resistive element.

Potentiometer Configurations

Whether you’re adjusting the gain on an amplifier, changing the speed of a fan, or tuning an oscillator, potentiometers serve as intuitive control elements. Their wide usability is due in part to their internal structure, which always includes two end terminals and a third movable contact known as the “wiper.”

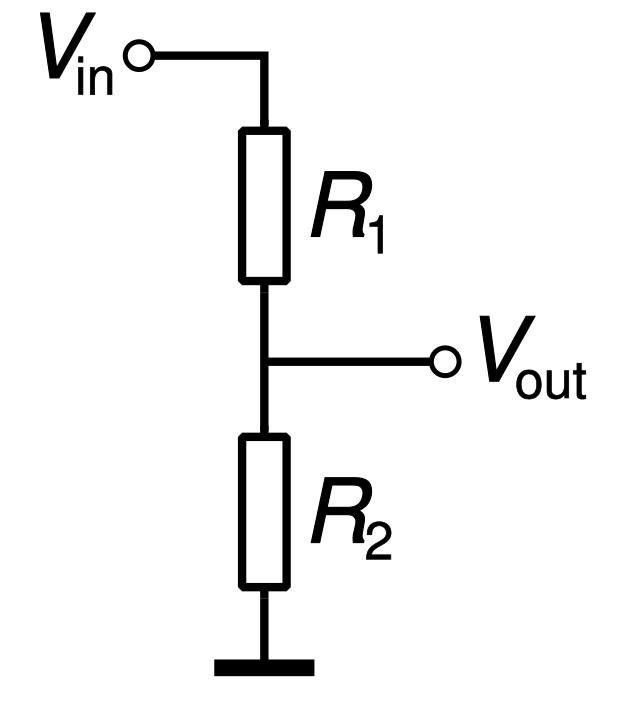

When used as a potentiometer, all three terminals are connected: both ends of the resistive track and the wiper. This configuration acts as a voltage divider, where the output voltage (from the wiper) varies depending on its position between the two fixed ends. As you turn or slide the control, the resistance on either side of the wiper changes proportionally, adjusting the voltage seen at the output.

In contrast, when used as a variable resistor, only one end of the resistive track and the wiper are connected. This two-terminal setup controls current flow by altering resistance — effectively acting like a volume knob for current. In high-current applications like controlling motors or lamps, these are known as rheostats.

Sometimes, the unused terminal is electrically tied to the wiper to prevent the circuit from becoming open when the wiper moves to an extreme end. In such setups, a variable resistor behaves as a smooth, continuous resistance control across a wide range.

Types of Potentiometers

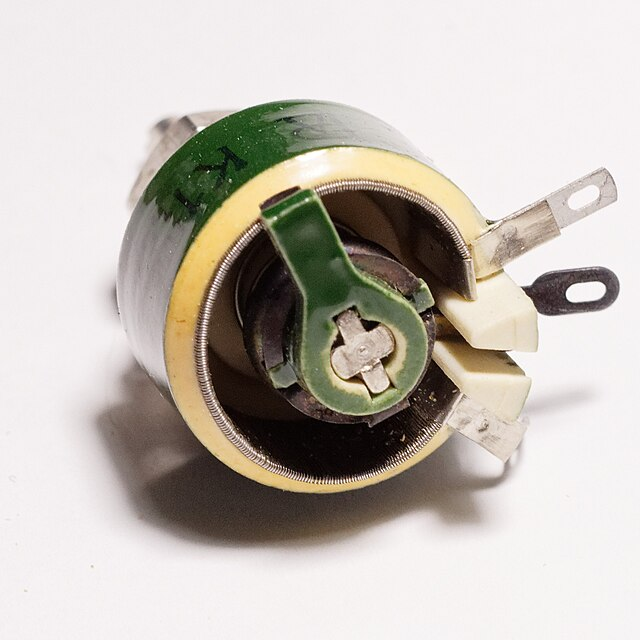

Potentiometers come in various mechanical forms, each suited for specific use cases. Regardless of the type, every potentiometer has two main parts: a resistive track (which defines the resistance value, like 10kΩ) and a mechanical wiper that moves across the track to adjust resistance.

Rotary Potentiometers

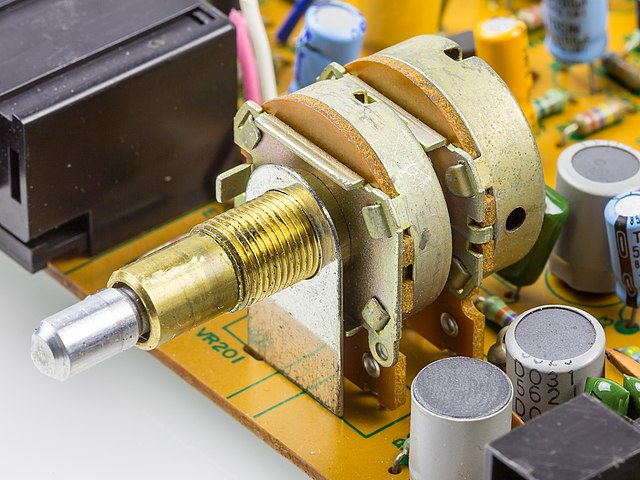

Rotary potentiometers, the most common type, operate via a rotating shaft that moves the wiper along a curved resistive element. They’re usually mounted on PCBs or control panels and are popular in audio applications like volume control. Some come with multiple tracks — known as “ganged” pots — which adjust multiple signals simultaneously (e.g., left and right stereo channels).

These rotary pots can have linear or logarithmic tapers, depending on whether you want even resistance change or a curve that matches human hearing. Single-turn variants typically offer less than 300° of movement, while multi-turn trimmer pots provide much finer resolution, often used in calibration circuits. Multi-turn versions may allow 3, 5, 10, or even 25 full turns to span their resistance range.

Slider Potentiometers

Slider potentiometers, or slide-pots, change resistance linearly by sliding a knob or handle across a straight path. They’re favored in audio mixers and graphic equalizers because their position visibly indicates the current setting. However, the open slot needed for movement can attract dust, dirt, or sweat, leading to degradation. Some designs add felt covers to protect the track.

In addition to adjusting electrical parameters, slide potentiometers can be used as position sensors. These linear displacement sensors convert physical movement into a voltage signal, useful for robotics, automation, and touch-sensitive controls.

Trimmers and Presets

Preset and trimmer potentiometers are small, fixed-location variable resistors used for one-time or occasional adjustments, such as tuning a circuit during manufacturing or field repair. Most are adjusted via a small screwdriver and come in either skeleton (open) or enclosed (sealed) types. The sealed versions are better protected and more stable, especially in environments with dust or moisture.

Multi-turn trimmers offer very fine adjustments and are available in through-hole or surface-mount forms for direct PCB integration. Although not meant for frequent tweaking, they’re crucial in applications where exact calibration matters, such as analog sensor circuits or voltage reference tuning.

Rheostats

Rheostats are heavy-duty, high-wattage variable resistors typically made with wire wound elements. They’re used to control large currents and dissipate substantial power. In a typical configuration, current enters through one terminal and exits through the wiper. Because all current flows through the wiper, it must be built to withstand mechanical wear and electrical load.

While any variable resistor can technically function as a rheostat, true rheostats are purpose-built for industrial uses where heat and load capacity matter. You’ll find them in motor controls, lamp dimmers, and test setups requiring adjustable power dissipation.

Technology & Construction

Potentiometers are available in different technologies like carbon film, conductive plastic, cermet, and wirewound. Each has its own characteristics for tolerance, temperature stability, and mechanical wear. The resistance rating (e.g., 10kΩ) indicates the full resistance between the two end terminals. This value can be as low as a few ohms or as high as several megaohms, depending on the application.

In terms of function, a potentiometer mimics a voltage divider circuit made from two resistors in series. The wiper position effectively splits the resistive track into two segments, and as the position changes, so does the output voltage proportionally. Because of this, potentiometers are often used to generate reference voltages or control input levels.

Practical Applications

In this sense, they serve both mechanical and electrical roles: converting physical input into a precise voltage signal. That’s why they remain a popular choice for user interfaces, tuning circuits, and even sensing motion. Their simple yet powerful role in electronic systems makes them one of the most important passive components in electrical engineering.

🛠 Fun Fact: The volume knob on most analog radios? That’s a potentiometer. And so is the joystick in your game controller. These versatile devices quietly handle your inputs every day.

Whether you’re adjusting sound, light, speed, or signal gain — if there’s a dial or slider involved, chances are a potentiometer is doing the job.

Recommended Potentiometers (Affiliate Links)

- Potentiometer Kit for Arduino – Buy on Amazon

- Trimmer Potentiometer Assortment Kit – Buy on Amazon

- Super Starter Kit Based on Arduino UNO R3 – Buy on Amazon

These are affiliate links. If you make a purchase through them, I may earn a small commission at no extra cost to you. It helps support this blog and allows me to keep creating free content. Thank you!

Frequently Asked Questions (FAQ)

Q1: Can I use any potentiometer as a variable resistor?

Yes, by connecting only two terminals (one end and the wiper), you effectively turn a potentiometer into a variable resistor.

Q2: Why do some potentiometers feel “scratchy” when turned?

This is usually due to dirt or wear on the resistive track. It’s more common in open-frame rotary pots or slide potentiometers exposed to dust.

Q3: What’s the difference between linear and logarithmic potentiometers?

Linear potentiometers change resistance evenly across the rotation. Logarithmic pots change resistance exponentially — useful for audio control where human hearing is non-linear.

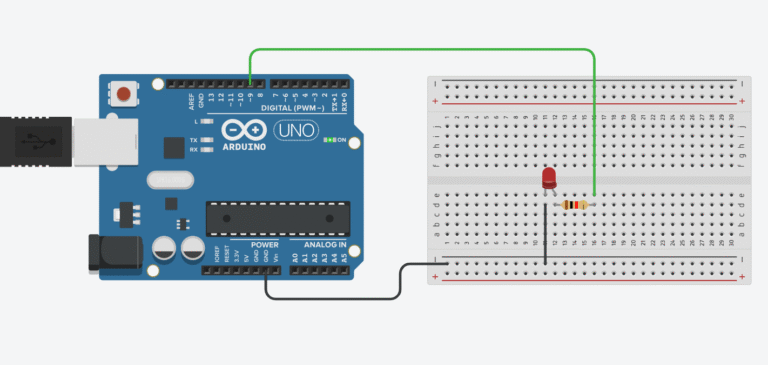

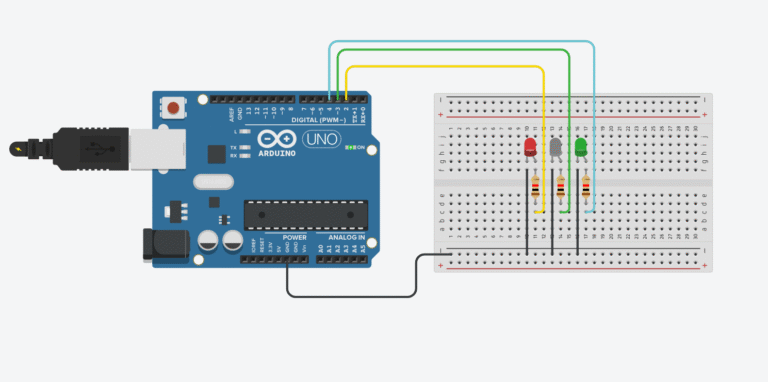

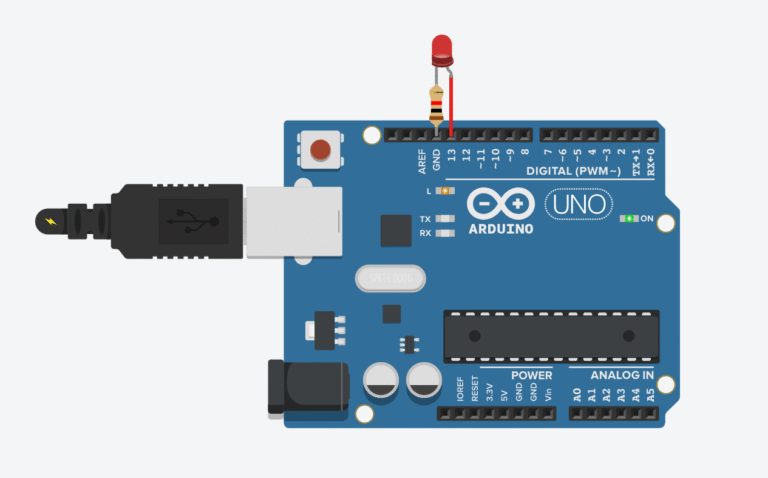

Q4: Can I use a potentiometer to control LED brightness?

Yes, in a simple voltage divider setup or as part of a transistor circuit, you can use a pot to dim LEDs.

Q5: How do I choose the right potentiometer value?

It depends on your circuit’s voltage and current needs. For signal-level work, 10kΩ or 100kΩ are typical. For power control, lower resistance values (like 1kΩ or less) are more common.