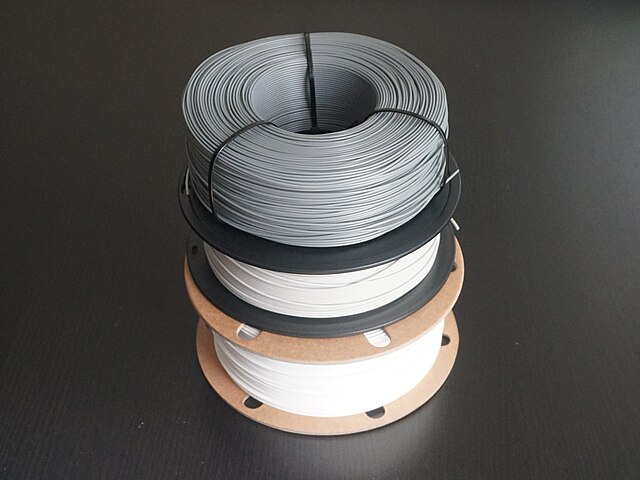

When it comes to 3D printing, filament diameter might seem like a small detail — but it plays a big role in print quality, extrusion performance, and even hardware compatibility. Choosing the right diameter can affect everything from layer resolution to nozzle jams, and the decision often influences the kind of printer, hotend, and slicer settings you’ll be using.

Let’s dig deep into the two main filament diameters and explore why it matters.

The Two Main Filament Sizes: 1.75mm vs 2.85mm (or 3.00mm)

The world of desktop 3D printing revolves around two primary filament diameters:

- 1.75mm – by far the most widely adopted standard

- 2.85mm – sometimes labeled as 3.00mm, found in specific printer ecosystems like Ultimaker

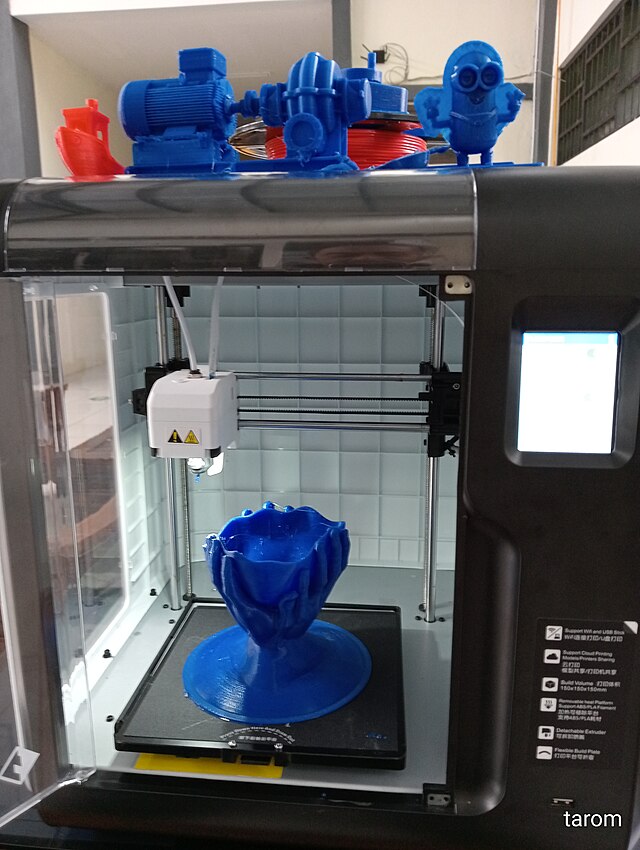

1.75mm – The Current Standard

The 1.75mm filament is the dominant choice for most consumer and prosumer 3D printers today. Brands like Creality, Anycubic, Prusa, and Bambu Lab all design their machines around this diameter.

Unlike older systems, modern hotends and extruders are optimized for this thinner filament size. It melts more evenly, flows with precision, and reacts more responsively to rapid retraction or flow changes — all of which are critical for printing detailed models or small mechanical parts.

Because of its small cross-sectional area, 1.75mm filament requires less force to push through the hotend. This not only reduces wear and tear on extruder gears but also makes it more compatible with compact direct drive setups. The rapid heating and cooling response of this size also enables faster and cleaner layer transitions.

However, 1.75mm filament does demand stricter quality control. Since it’s thinner, even a small inconsistency in diameter can cause under-extrusion, over-extrusion, or jamming — especially in Bowden-style printers where friction and flexibility are more pronounced. Budget filaments sometimes swell or flatten slightly, creating friction points in PTFE tubing.

It’s a good habit to occasionally check the filament diameter with a caliper before important prints. Even well-known brands can vary slightly, and a ±0.05mm deviation is enough to ruin fine-detail models. Slicer adjustments like flow rate tuning or adaptive line width can help mitigate inconsistencies, but only if you know they exist.

Overall, 1.75mm offers excellent balance for precision, control, and availability. Unless you have a specific need for higher throughput, this is the filament size you’ll want to build your printer setup around.

👉 Recommended: Overture PLA+ 1.75mm

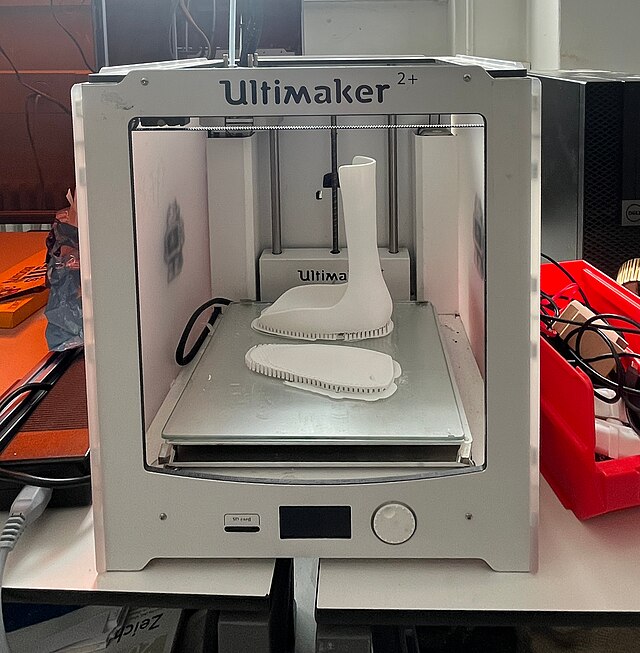

2.85mm – The Niche Heavyweight

2.85mm filament (often mislabeled as 3.00mm) is found mostly in printers designed by Ultimaker and some older LulzBot models. It’s chunkier, stiffer, and moves more material, and while it isn’t as widely used as 1.75mm, it does have specific advantages.

Because of its rigidity, 2.85mm filament performs well in long Bowden tube systems. It’s more resistant to buckling under compression and offers smoother feeding when combined with powerful extruder motors. This makes it particularly suitable for printers that require high material throughput or are used in fast, high-volume production.

The thicker diameter also reduces the need for precise micro-stepping in extrusion. Since more filament comes out per rotation of the gear, it’s easier to push large amounts of material quickly, which is useful for printing big objects or using large nozzles (e.g. 0.6mm and above).

However, it’s harder to achieve high-resolution prints with 2.85mm, especially on very small models. The retraction isn’t as snappy, and fine flow control is more difficult. Some slicers may require tuning to compensate for the thicker feed. Additionally, filament availability is limited, with fewer color options and higher costs.

Unless your printer was explicitly built for 2.85mm, it’s better to stick with the more flexible and finely controllable 1.75mm format.

👉 Recommended: Polymaker PLA PRO Filament

Why Diameter Consistency Matters

No matter the filament size, consistency is critical. Irregular diameters — even minor ones — can disrupt the flow rate, cause blobs or gaps in walls, or result in nozzle clogs. You might notice layer artifacts, fluctuating extrusion width, or even total print failure.

Manufacturers usually state a tolerance range (e.g., ±0.02mm or ±0.03mm). The tighter the tolerance, the more reliable the filament. Poor-quality spools may have sudden diameter changes, causing your extruder to overcompensate or grind into the filament.

Use a digital caliper to take several measurements along the filament’s length. If the diameter varies significantly, consider compensating by adjusting your slicer’s flow rate or simply replacing the filament.

FAQ – Frequently Asked Questions

Is 1.75mm filament better than 2.85mm?

For most users — yes. 1.75mm filament allows for finer control, better detail, and is compatible with the majority of modern consumer printers. It’s also easier to find and typically cheaper. However, 2.85mm has the edge in high-volume extrusion and works better in long Bowden tubes.

Why do some manufacturers still use 2.85mm?

Primarily for historical and proprietary reasons. Brands like Ultimaker built ecosystems around 2.85mm, and it performs well in industrial environments that require high-speed printing with larger nozzles. It’s also more resistant to bending or jamming over long filament paths.

Can I convert my printer from 2.85mm to 1.75mm?

Technically yes — but it’s not always practical. You’d need to replace the extruder, hotend, and possibly firmware settings. Unless you have strong reasons to switch, it’s easier to stick with what your printer was designed for.

Does filament diameter affect print strength or quality?

Indirectly. The diameter itself doesn’t define strength, but inconsistent diameter can cause under- or over-extrusion, affecting wall thickness, bonding, and surface finish. Consistency and print settings play a bigger role than size alone.

How do I measure filament diameter accurately?

Use a digital caliper and take multiple readings along different sections of the filament. Average them to get a realistic profile, and watch for sudden jumps. Enter the measured average into your slicer for better extrusion accuracy.

Final Thoughts

If you’re printing on a modern consumer printer, 1.75mm is the default choice for good reason: it’s precise, responsive, widely supported, and easy to source. It works great for everything from fine-detail models to functional mechanical parts.

2.85mm, on the other hand, is best suited for specialized machines or industrial workflows that prioritize speed and volume over resolution.

Whichever diameter you choose, always check for tight tolerances and keep an eye on extrusion behavior — because even the smallest inconsistency can ruin a print.

Recommended Starter Gear (Affiliate Links)

- Bambu Lab A1 Mini + AMS Lite

- Elegoo Mars 4 Ultra

- Overture PLA+ filament

- Elegoo Standard Resin

- Wash & Cure Station

🛒 Some links above are affiliate links, which help support this blog. Thanks!