3D printing, also known as additive manufacturing, is a process of creating three-dimensional objects by depositing material layer by layer based on a digital model.

Unlike traditional manufacturing methods such as CNC machining or injection molding — which are subtractive or mold-based — 3D printing builds objects from the ground up, allowing for complex geometries, rapid prototyping, and on-demand production with minimal material waste.

How 3D Printing Works

The workflow for 3D printing typically involves three main stages:

Designing the Model

- The process starts with a digital 3D model, often designed in CAD software like Fusion 360, SolidWorks, or Blender.

- The model is exported as an STL, OBJ, or 3MF file — standard formats used for slicing.

Slicing the Model

- Slicer software (such as Cura, PrusaSlicer, or Bambu Studio) converts the 3D model into G-code — the instructions that the printer will follow.

- This includes settings for layer height, print speed, temperatures, infill percentage, and support structures.

Printing the Object

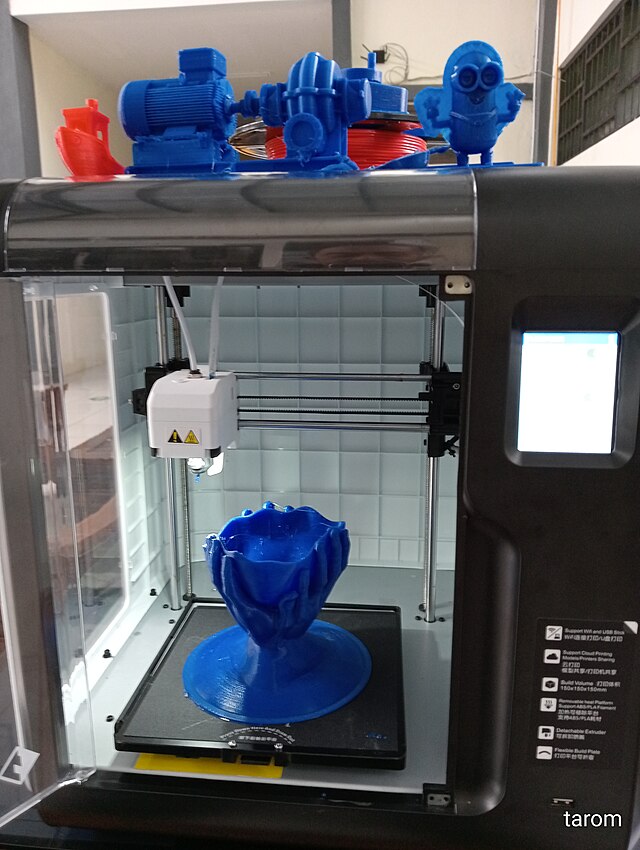

- The G-code file is sent to the 3D printer, which builds the object layer by layer.

- The most common type, FDM (Fused Deposition Modeling), melts thermoplastic filament and extrudes it through a heated nozzle.

- Other technologies include SLA (resin-based), SLS (powder-based), and more — each with specific use cases and material compatibility.

Common 3D Printing Technologies

FDM (Fused Deposition Modeling)

- Widely accessible and ideal for general prototyping.

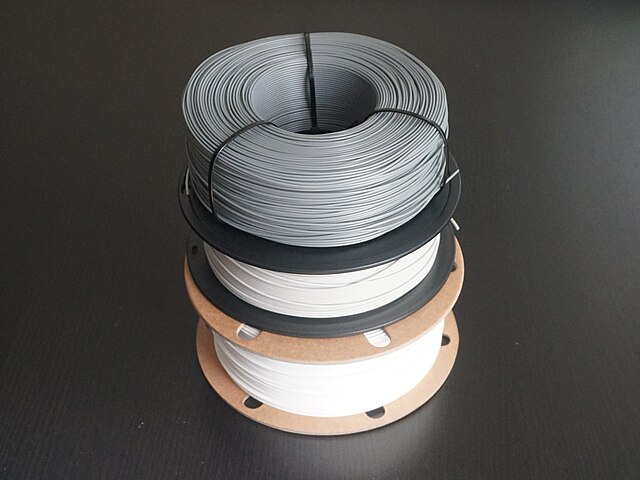

- Uses filament such as PLA, PETG, ABS, and TPU.

SLA (Stereolithography)

- Uses UV light to cure resin layer by layer.

- Offers higher resolution and surface finish but requires post-processing (washing, curing).

SLS (Selective Laser Sintering)

- Fuses powder materials using a laser.

- Used in industrial settings for durable, complex parts.

Materials Used in 3D Printing

- PLA (Polylactic Acid): Easy to print, biodegradable, low warp.

- ABS (Acrylonitrile Butadiene Styrene): Stronger and more heat-resistant, but requires controlled environment.

- PETG (Polyethylene Terephthalate Glycol): Combines ease of use with strength and durability.

- TPU (Thermoplastic Polyurethane): Flexible, rubber-like, used for gaskets and wearable parts.

- Resins: Various types for SLA printing, including standard, tough, flexible, and high-temp.

Applications of 3D Printing

- Prototyping and Product Development

- Functional Parts and Tooling

- Custom Enclosures and Fixtures

- Medical Models and Implants

- Educational and Hobbyist Projects

Getting Started

- To start 3D printing, you’ll need:

- A 3D printer (FDM is most beginner-friendly)

- Slicing software

- Filament or resin

- Basic tools (e.g., scraper, calipers, isopropyl alcohol for cleaning)

Maintenance is also key: keeping your nozzle clean, leveling your bed, and storing materials properly ensures consistent results.

3D printing is not just a trend — it’s a transformative tool for design, engineering, and creativity. Whether you’re a hobbyist, a maker, or part of a startup team, understanding the fundamentals gives you a head start in using this technology effectively.

In upcoming posts, we’ll dive deeper into topics like printer calibration, slicer settings, material selection, and troubleshooting prints.

Stay tuned, and start building.