3D printing, also known as additive manufacturing, is a process of creating three-dimensional objects by adding material layer by layer based on a digital model. Unlike traditional subtractive methods, where material is carved or cut away, additive manufacturing builds objects from the ground up—making it more efficient for complex geometries and reducing material waste.

There are various methods of 3D printing, but three of the most commonly used technologies are Fused Deposition Modeling (FDM), Stereolithography (SLA), and Selective Laser Sintering (SLS). Each technology has its own unique mechanisms, materials, advantages, and ideal applications. Let’s break them down in technical detail.

Fused Deposition Modeling (FDM)

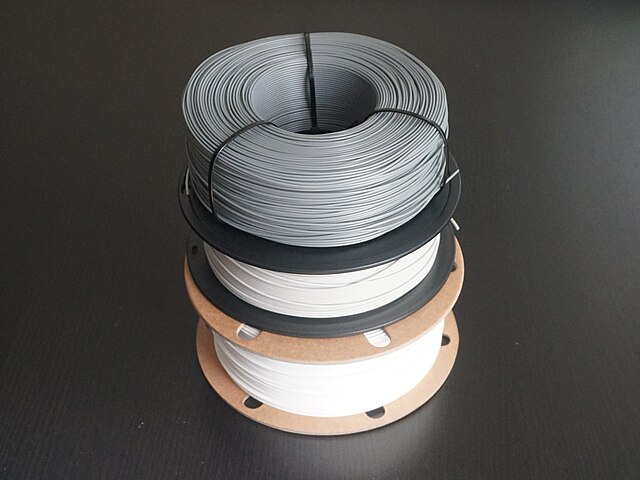

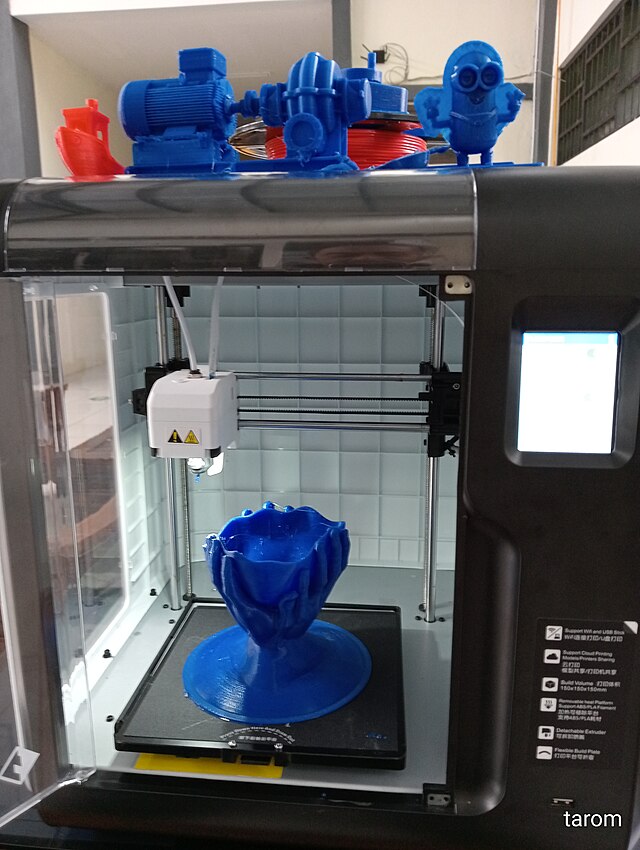

FDM is the most widely adopted 3D printing technology, especially in the consumer and educational sectors. The process begins with a thermoplastic filament—such as PLA, PETG, or ABS—fed into a heated extruder. The filament is melted and deposited through a nozzle onto a build platform, one layer at a time, following the toolpath generated from slicing the 3D model into layers.

The print head moves in X and Y directions while the bed typically moves in Z. The molten plastic solidifies upon cooling, bonding with the previous layer to build the object. FDM machines usually employ stepper motors and G-code instructions to control movement and extrusion.

Print quality is influenced by factors such as layer height, nozzle diameter, temperature control, and cooling. Common layer heights range from 0.1mm to 0.3mm, and a 0.4mm nozzle is the standard. Cooling fans are used to quickly solidify the filament, especially for materials like PLA that benefit from rapid cooling.

Despite being relatively affordable and easy to operate, FDM prints often exhibit visible layer lines and may require supports for overhangs. The technology is ideal for rapid prototyping, mechanical parts, and functional models where high detail is not a priority.

Recommended FDM setup: BamBu Lab A1 mini + Overture PLA+ filament

Stereolithography (SLA)

SLA was the first 3D printing technology ever developed and remains one of the most precise. Instead of extruding filament, SLA uses a vat of photopolymer resin and a light source—either a laser or an LCD screen—to cure the resin selectively. The build platform starts just above the bottom of the resin tank and gradually rises as each layer is cured.

The curing process is based on photopolymerization, where UV light solidifies the liquid resin into rigid plastic. The laser or light source traces the cross-section of the model layer by layer, hardening the resin only in the desired regions. The resolution of SLA prints is primarily defined by the XY resolution of the light source (e.g., LCD pixel size or laser spot diameter) and the Z resolution, which is often adjustable down to 25 microns.

Once printing is completed, SLA prints require extensive post-processing: rinsing in isopropyl alcohol (or a wash station) to remove uncured resin, followed by UV curing in a dedicated chamber. Resin handling must be done with gloves and proper ventilation due to its chemical nature.

SLA produces exceptionally detailed and smooth parts, making it perfect for applications like dental models, jewelry prototypes, figurines, and precision engineering. However, resins are more expensive, and the entire workflow is messier and more demanding than FDM.

Starter SLA combo: Elegoo Mars 4 Ultra + Elegoo Standard Resin + Wash & Cure Station

Selective Laser Sintering (SLS)

SLS is a powder-based 3D printing process used primarily in industrial settings. The process starts by spreading a thin layer of polymer powder—most commonly nylon—across the build chamber. A high-powered laser then selectively sinters (heats and fuses) the powder particles together according to the design.

After each layer is sintered, a new layer of powder is spread over the previous one, and the process repeats until the part is complete. The unsintered powder remains in place during printing, which acts as a natural support structure. This allows SLS to produce highly complex geometries, internal cavities, and interlocking parts without support material.

Cooling and depowdering are critical stages post-printing. The entire powder bed needs time to cool gradually to prevent warping. After cooling, the parts are extracted and cleaned, often using compressed air or bead blasting.

SLS parts are strong, durable, and suitable for end-use applications. The technology is widely used in aerospace, automotive, and medical industries for functional prototypes and production-grade components. However, the equipment is expensive, and operation requires specialized knowledge, making it less accessible for casual users.

FAQ – Common Questions About FDM, SLA, and SLS

Is FDM cheaper than SLA?

Yes, FDM printers and filament are generally more affordable and easier to use. SLA costs more due to resin prices and post-processing requirements.

Can SLS be used at home?

Not yet. SLS printers are still mostly industrial-grade, but desktop versions are emerging. They remain expensive and require more technical know-how.

Which process gives the best surface finish?

SLA wins for surface finish and detail sharpness. FDM is good for strength, and SLS balances both with added complexity.

Is resin toxic?

Uncured resin can be harmful. Always wear gloves, work in a ventilated area, and fully cure your prints.

Which one should I choose as a beginner?

Go for FDM. It’s cheaper, safer, and more forgiving. The Bambu Lab A1 Mini + AMS Lite is a solid choice to start.

Conclusion

Each 3D printing technology—FDM, SLA, and SLS—offers distinct benefits and is suited for different types of applications. FDM is ideal for affordable functional prototyping, SLA is unmatched in surface finish and detail, and SLS excels in strength and complexity.

Understanding how each works helps you choose the right tool for your job—whether you’re printing a mechanical bracket, a display model, or an industrial-grade component.

(Affiliate links are included. They help support this blog at no extra cost to you. Thanks for the support!)