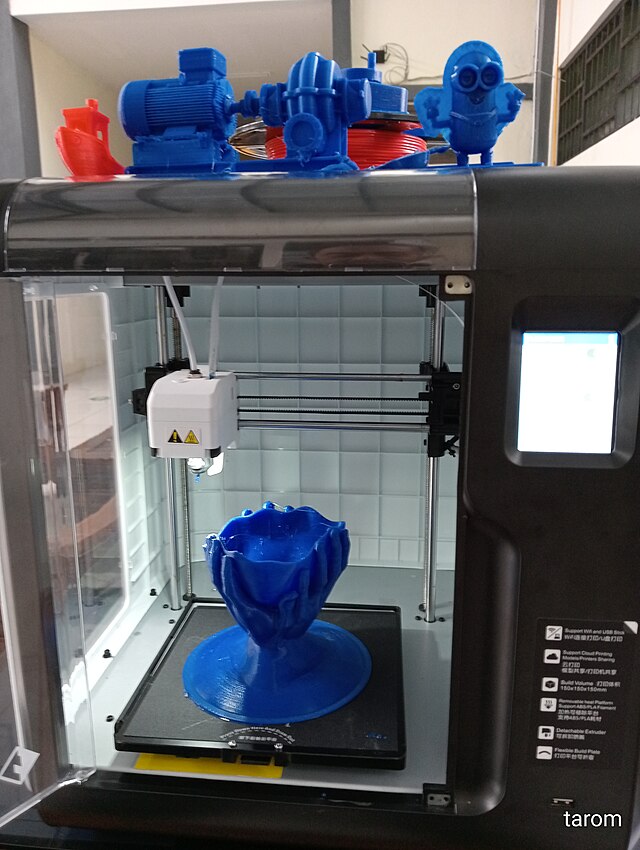

As you level up in 3D printing, you’ll quickly find that PLA, ABS, and PETG can’t do it all. Need something flexible? Heat-resistant? Glow-in-the-dark? That’s where advanced materials like TPU, Nylon, and exotic filaments step in. These aren’t just flashy alternatives — they’re specialty materials designed for very specific use cases. Let’s break them down.

TPU – Thermoplastic Polyurethane

TPU is your go-to material when flexibility matters. It’s a rubber-like filament that can bend, compress, and stretch without breaking. If you’ve ever seen a 3D-printed phone case, RC car tire, or grommet, chances are it was made of TPU.

It prints at 220–250°C with a heated bed around 40–60°C. TPU doesn’t need an enclosure, but it does require slow print speeds (20–40 mm/s) and direct drive extruders are strongly recommended. Bowden setups can work, but it’s a lot more hassle due to TPU’s softness.

TPU is shock-absorbing, abrasion-resistant, and chemically durable. It comes in varying degrees of hardness (measured in Shore A), letting you choose just how squishy you want your part to be.

👉 Best use: phone cases, wheels, seals, vibration dampeners, hinges.

👉 Avoid for: unsupported vertical details, high-precision parts.

👉 Recommended: Overture TPU

Nylon – Polyamide

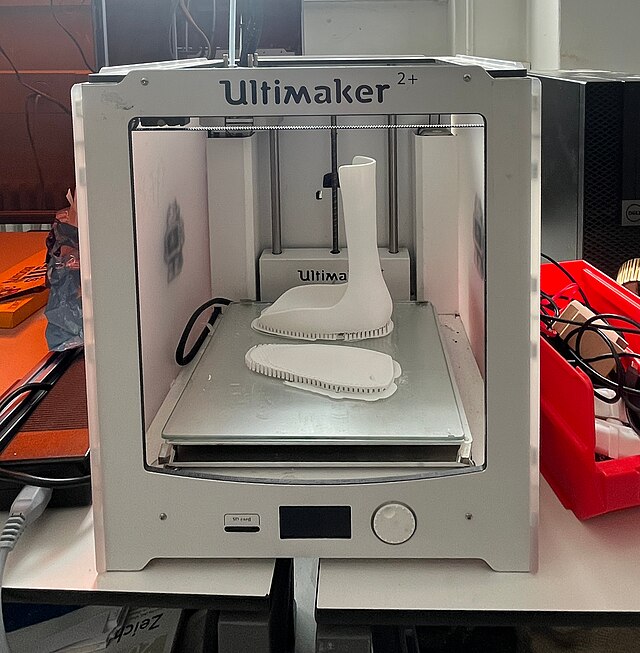

Nylon is incredibly strong, tough, and slightly flexible, which makes it ideal for functional parts under mechanical stress. Think gears, hinges, and engineering components. It’s also heat-resistant and wear-resistant, making it perfect for demanding environments.

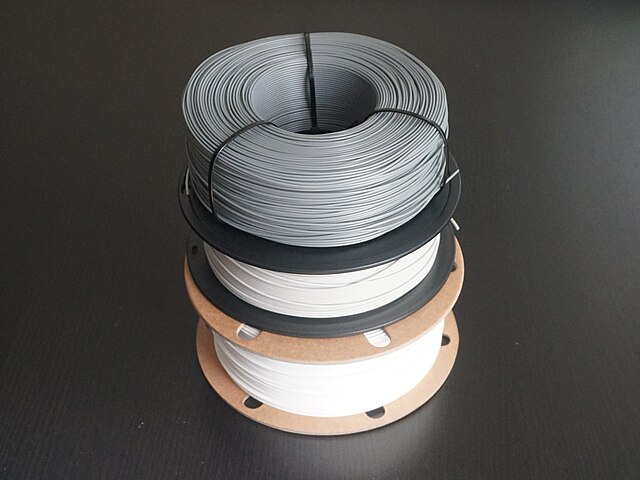

Nylon prints at 240–280°C and needs a heated bed at 70–100°C. It strongly benefits from an enclosure to prevent warping and must be kept dry — it’s extremely hygroscopic. Even a few hours of exposure to air can degrade print quality, so store it in a dry box or oven-dry before use.

It’s not the easiest filament to print, but the mechanical properties are worth it. You’ll also want to use a Garolite build surface or glue stick for adhesion.

👉 Best use: gears, tools, brackets, engineering parts.

👉 Avoid for: purely aesthetic models, users without an enclosure or dry storage.

👉 Recommended: Polymaker Nylon Filament + Creality Official Filament Dryer Box

Exotic Filaments – Wood, Metal, Glow-in-the-Dark & More

If you want to push the visual or functional boundaries of your prints, exotic filaments are where things get fun. These are composite materials — base filaments like PLA or PETG blended with other substances to give them special effects or finishes.

- Wood-filled PLA contains real wood fibers and looks/smells like wood. Great for aesthetic pieces, but needs a hardened steel nozzle to avoid wear.

- Metal-filled PLA (like copper or bronze) gives prints a metallic finish and can even be polished. It’s heavier and a bit brittle.

- Glow-in-the-dark filaments are just fun, but can wear nozzles quickly.

- Carbon fiber reinforced filaments (PLA, PETG, or Nylon base) are super stiff and lightweight — ideal for drones, brackets, or structural frames. These require a hardened nozzle and careful tuning.

Printing requirements vary, but all exotic filaments are harder on your printer than standard PLA. They can be abrasive and often require upgraded nozzles, slower speeds, and proper bed adhesion setups.

👉 Best use: showpieces, cosplay props, functional structural parts (carbon fiber).

👉 Avoid for: fine mechanical parts without testing, stock brass nozzles.

👉 Recommended: SUNLU Wood PLA, ColorFabb BronzeFill, Priline Carbon Fiber PLA

Pro Tips & Warnings for Advanced Filaments

Once you move beyond PLA and PETG, advanced filaments unlock serious potential — but they also come with new challenges. Here’s what you need to know before diving in:

Hardware Upgrades

- Direct drive extruder: Almost mandatory for TPU. It gives tighter control and prevents filament buckling.

- All-metal hotend: Needed for printing at 240°C+, especially Nylon. PTFE-lined hotends will degrade.

- Hardened steel nozzle: Required for carbon fiber, metal-filled, and glow-in-the-dark filaments. These materials are abrasive and will quickly wear out brass.

- Enclosure: Greatly improves print quality for Nylon by keeping heat stable and reducing warping.

Moisture Control

TPU and Nylon are highly hygroscopic — they absorb moisture from the air fast. Wet filament causes stringing, popping sounds, and weak prints. Always store in dry boxes or re-dry before use using a filament dryer or low-temp oven.

Print Tuning Essentials

Each filament has quirks. Here’s a cheat sheet:

| Filament | Hotend Temp | Bed Temp | Retraction | Cooling Fan | Notes |

|---|---|---|---|---|---|

| TPU | 220–250°C | 40–60°C | Low (0.5–1mm) | Off | Print slow (20–40 mm/s), needs direct drive |

| Nylon | 240–280°C | 70–100°C | Moderate (2–5mm) | Off | Needs enclosure, must be dry |

| Carbon Fiber PLA | 210–220°C | 50–60°C | Normal (4–6mm) | 20–40% | Hardened nozzle required, very stiff |

| Wood-Filled PLA | 200–220°C | 50°C | Normal | Low | Use 0.6mm+ nozzle, prints look & smell like wood |

| Metal-Filled PLA | 200–220°C | 50–60°C | Normal | Off | Heavy prints, abrasive, polishable |

| Glow-in-the-dark | 200–220°C | 50°C | Normal | On | Very abrasive, dries before use |

Common Mistakes to Avoid

- Using a brass nozzle with abrasive filament? Don’t. You’ll wear it out in a few hours.

- Printing TPU too fast? It’ll jam or under-extrude.

- Storing Nylon in the open air? Expect stringy, ugly prints.

- Using retraction on TPU like it’s PLA? Nope. Keep it minimal.

FAQ – Advanced Filaments

Is TPU harder to print than PLA?

Yes. TPU is flexible, which makes it tricky to feed and print. Use slow speeds and direct drive extruders.

Can I use my normal nozzle for carbon fiber or metal filaments?

No. These are abrasive and will wear down brass nozzles quickly. Use hardened steel or ruby nozzles.

Why is my Nylon filament popping and stringing?

It’s absorbed moisture. Dry it before printing using a filament dryer or oven.

Are exotic filaments just for looks?

Not always. While many are visual gimmicks, some like carbon fiber-filled materials offer real mechanical advantages.

Is TPU food safe?

Technically yes, but print quality, cleanliness, and the extruder system matter. Use food-safe brands and consider post-processing.

Final Thoughts

Once you’ve mastered basic filaments, exploring TPU, Nylon, and exotic blends opens a world of creative and functional potential. Just know that these materials often require more tuning, special hardware, and practice to get right.

But when done right? You’ll unlock designs that would be impossible with standard materials.

Recommended Starter Gear (Affiliate Links)

- Bambu Lab A1 Mini + AMS Lite

- Elegoo Mars 4 Ultra

- Overture PLA+ filament

- Elegoo Standard Resin

- Wash & Cure Station

🛒 Some links above are affiliate links — they help support the blog. Thanks!