When most people hear “3D printing,” they picture a desktop machine slowly drawing shapes in melted plastic. And yeah — that’s a huge part of it. But 3D printing is more than just a plastic noodle machine. It’s a whole world of tools, materials, and technologies, each with different strengths and quirks.

In this guide, we’ll break down the three most common 3D printing technologies today: FDM, SLA, and MSLA (resin printing). We’ll cover how they work, what kind of materials they use, the pros and cons of each, and which one actually fits your goals and your budget.

FDM – The Practical Choice for Makers Who Want Functionality

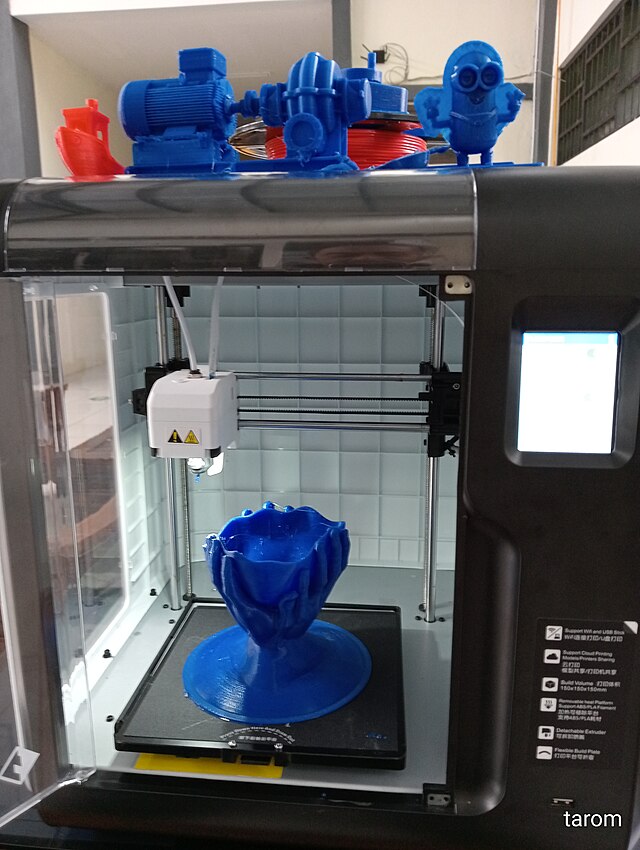

FDM (Fused Deposition Modeling) is the most beginner-friendly and widely used 3D printing method. It works by melting a spool of plastic filament and pushing it through a heated nozzle, laying it down layer by layer to build your model. Think of it like a very precise hot glue gun on a robot arm.

One reason FDM is so popular is because it’s incredibly accessible. You can get a solid printer for under $300, and filament is cheap and widely available. A great entry-level option is the Bambu Lab A1 Mini + AMS Lite , known for its ease of use and fast setup.

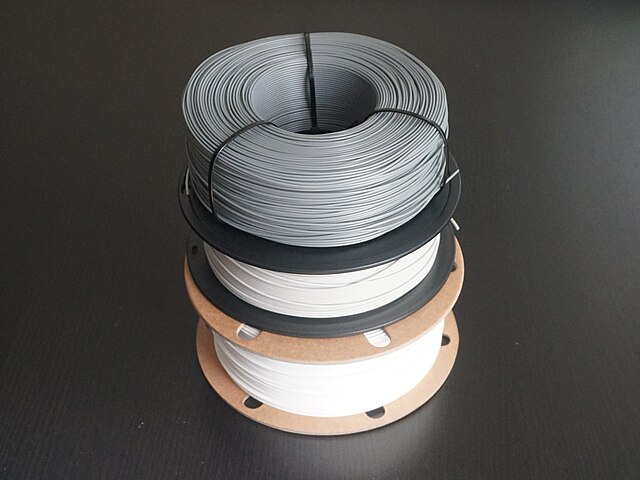

Most FDM printers use materials like PLA, PETG, and ABS:

PLA (Polylactic Acid) is the most beginner-friendly filament. It prints easily at lower temperatures, sticks well to the print bed, and doesn’t require a heated enclosure. It’s biodegradable and available in tons of colors and finishes, from matte to silk to wood-filled. However, PLA is brittle and doesn’t hold up well under heat — don’t leave it in a hot car.

If you want something stronger, PETG offers more durability and some flexibility, making it great for mechanical parts or outdoor use. ABS, on the other hand, is tougher and more heat-resistant but harder to print due to warping and strong fumes.

In short, FDM is ideal for functional parts, large prints, and everyday DIY use. The layer lines are visible, and it may not capture ultra-fine detail, but for practical work? FDM gets the job done.

SLA – For High Detail and Beautiful Surfaces

SLA (Stereolithography) flips the FDM process on its head. Instead of melting plastic, SLA printers use a UV laser to cure liquid resin layer by layer. This results in astonishingly smooth surfaces and ultra-fine details that look nearly injection-molded.

SLA shines in applications like miniatures, jewelry prototypes, dental models, and anything where visual quality matters more than strength. The detail is jaw-dropping — small text, intricate curves, and razor-sharp features come out effortlessly.

SLA printers use photopolymer resin, a liquid that hardens under UV light. There are different types:

- Standard resin: great detail, brittle, ideal for display

- ABS-like resin: better durability for light functional use

- Flexible/tough resin: for specific use cases, like wearable parts

But let’s not sugarcoat it: resin printing is messy. You’ll need gloves, isopropyl alcohol (IPA) to clean prints, and a curing station to harden them. Resin has a strong smell, can irritate skin, and needs careful handling.

Still, if you’re chasing perfection in detail, SLA delivers. Just be ready for a workflow that includes gloves, cleanup, and post-curing. A great resin to start with is the Elegoo Standard Photopolymer Resin.

MSLA – Resin Printing for Hobbyists on a Budget

MSLA (Masked Stereolithography) is SLA’s faster, more affordable cousin. It uses an LCD screen to mask a UV light source and cure entire layers of resin all at once, rather than tracing them with a laser.

This approach makes MSLA printers like the Anycubic Photon Mono 2 or Elegoo Mars 4 Ultra not only faster but also more cost-effective. It’s become the go-to solution for hobbyists looking to produce highly detailed miniatures or display models without spending a fortune.

MSLA still gives you all the resin benefits: buttery-smooth surfaces, ultra-sharp detail, and a finish that looks professional right off the build plate. It’s great for printing batches of small parts since each layer takes the same amount of time, no matter how many items are on the plate.

But it’s not without the usual resin downsides. You still need to deal with gloves, IPA, sticky cleanup, and UV curing. Plus, ventilation is a must — resin can smell pretty awful. Prints are often brittle unless you’re using specialty resins.

Despite the learning curve, once you get comfortable with the resin workflow, MSLA offers some of the best-looking results you can achieve without stepping into industrial territory.

So… Which One Should You Choose?

If you’re just getting into 3D printing and want a machine that’s easy to use, reliable, and practical, FDM is your best bet. It’s perfect for larger prints, functional parts, and everyday projects. PLA is easy to handle, and the workflow is beginner-safe.

But if your goal is to create gorgeous, show-off-worthy models with ultra-fine detail — like miniatures, props, or design prototypes — then resin printing (SLA or MSLA) is where the magic happens. It takes more effort, sure, but the results are undeniably worth it.

Many makers end up using both: FDM for strength, resin for detail. And honestly? Once you try both, you’ll understand why.

FAQ – Quick Answers for First-Time Buyers

Which is stronger: FDM or resin prints?

FDM prints are generally stronger and more durable. Resin prints are more brittle, especially under stress or impact.

Is resin dangerous?

Resin can be harmful if mishandled. Always wear gloves, work in a well-ventilated area, and fully cure your prints before use.

What’s the easiest printer for beginners?

FDM printers like the Kobra 2 Neo or Ender 3 V3 SE are the easiest and most forgiving for beginners.

Can I print functional parts with resin?

Yes, but only with tough or ABS-like resin. Standard resin is better suited for decorative or low-load applications.

Is it okay to run a resin printer indoors?

Yes, but only with good ventilation or an air purifier. Resin fumes can be unpleasant and potentially unsafe in small, closed rooms.

Recommended Starter Gear (Affiliate Links)

- Bambu Lab A1 Mini + AMS Lite

- Elegoo Mars 4 Ultra

- Overture PLA+ filament

- Elegoo Standard Resin

- Wash & Cure Station

(As an Amazon Associate, I earn from qualifying purchases. It helps support the blog — thanks!)